Product Solutions

Toy Printing Solutions

As market demands escalate for intricate toy designs, advanced printing processes must adapt precisely to diverse 3D shapes while maintaining seamless pattern alignment across curved and flat surfaces. Current manual multi-color registration methods, prone to positioning errors and inefficiency, hinder color consistency and edge definition in complex patterns. Automating precision multi-color printing emerges as a critical pathway for transforming toy manufacturing into intelligent, high-end production systems.

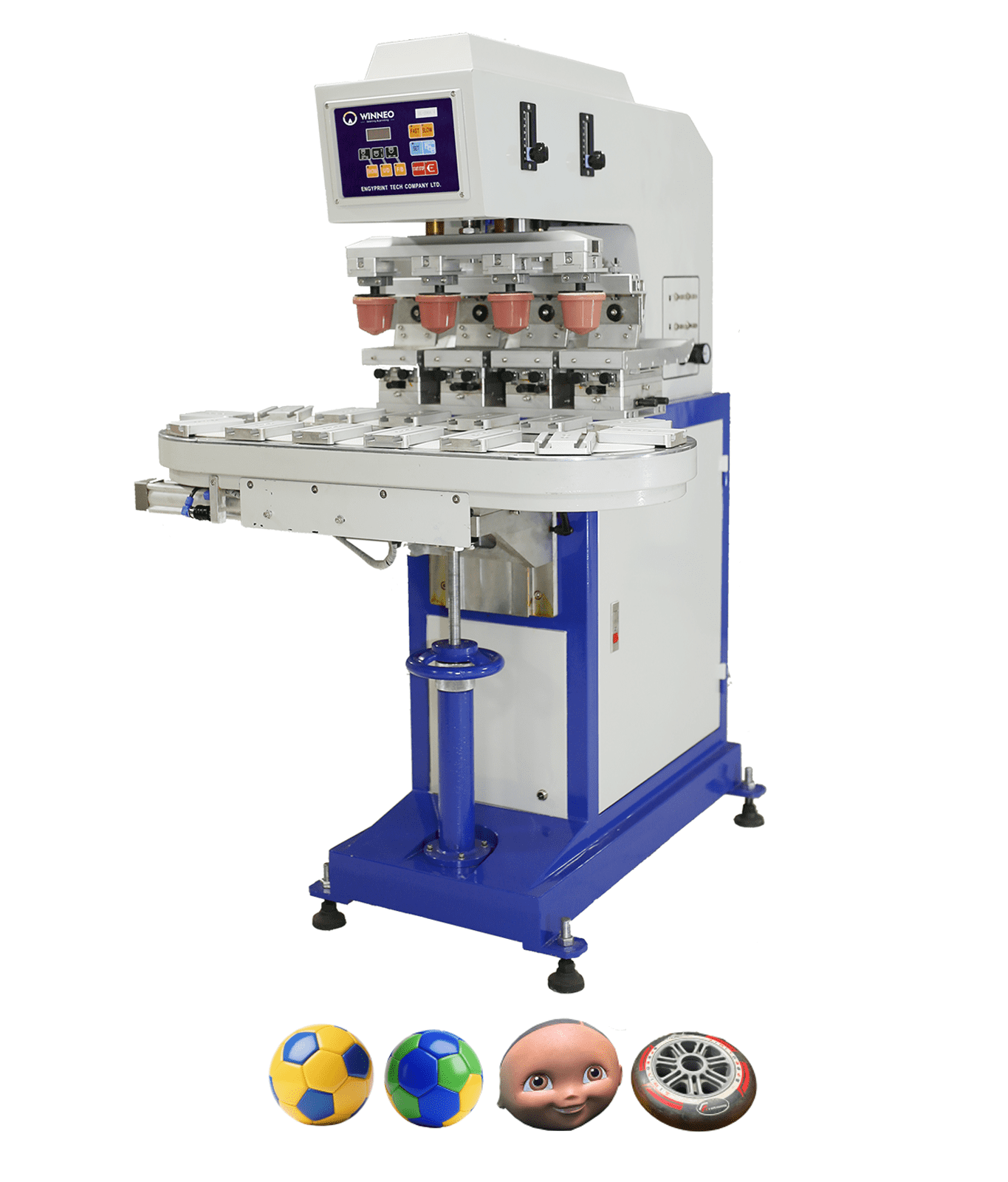

To meet the toy printing industry's needs for diversified patterns and safety and environmental protection, we provide a full range of multifunctional pad printing and screen printing machines, combined with cutting-edge technology to ensure printing quality and production efficiency.

Toy pad printing machines are widely used for surface printing of plastic toys, plush toys, wooden toys, rubber toys, etc. The materials that can be processed include ABS plastic, PVC, silicone, plush fabrics, wood, etc., and support water-based environmentally friendly ink printing, strictly follow toy safety standards, and protect children's health.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30