Industry Concerns & Pain Points

Cosmetic Labeling Printing Needs & Challenges

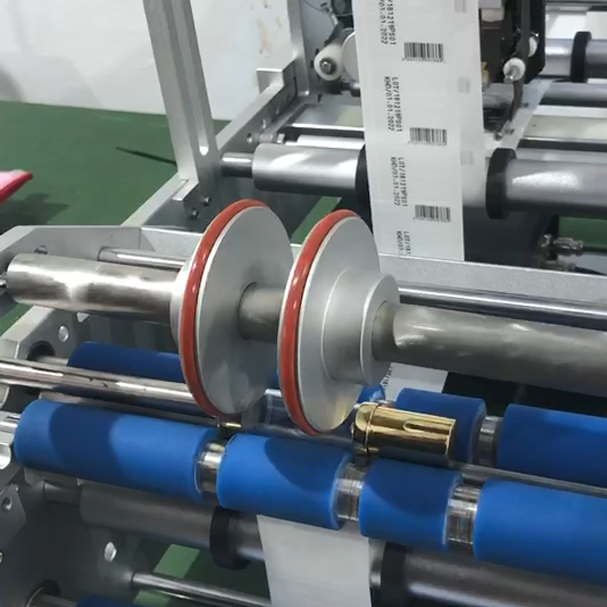

High efficient labeling and printing

High-speed production lines cannot tolerate pauses. We need the labeling system to synchronize the production capacity rhythm: zero-stop continuous operation, minimize debugging time, so that each bottle of product can seamlessly connect to the production process and fully release the production capacity value.

Beauty product printing and labeling quality standards

Appearance is competitiveness - the label must become the "second face" of the product: the color accurately restores the brand tone, the surface texture can withstand critical scrutiny, and from shelf display to user hands, it always maintains a "stunning at first sight" visual experience.

Simplify the operation process

Reject inefficient manual intervention! We pursue intelligent interactive interface: one-click switching of product parameters, automatic memory of historical settings, so that equipment operation changes from "time-consuming debugging" to "easy touch", greatly reducing labor costs and training thresholds.

Difficulties in adapting multi-form products

Round tubes, square bottles, special-shaped contours etc. The diversity of beauty packaging should not be an obstacle to production! We need the equipment to have flexible adjustment capabilities: the printing head adapts to the curvature of the surface, and the labeling accuracy is calibrated at the millimeter level to completely overcome the quality pain points such as "sticking crooked, wrinkling, and position deviation".

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30