Industry Needs & Challenges

Toy Printing Needs & Challenges

As a toy manufacturer, you need printing solutions that can handle a variety of materials - plastics, fabrics, woods, etc. Each material has unique surface properties that affect ink adhesion and drying. You need to ensure that printed patterns remain vibrant and durable, whether it's resisting friction on plastic toys or enduring repeated washings on fabric ones.

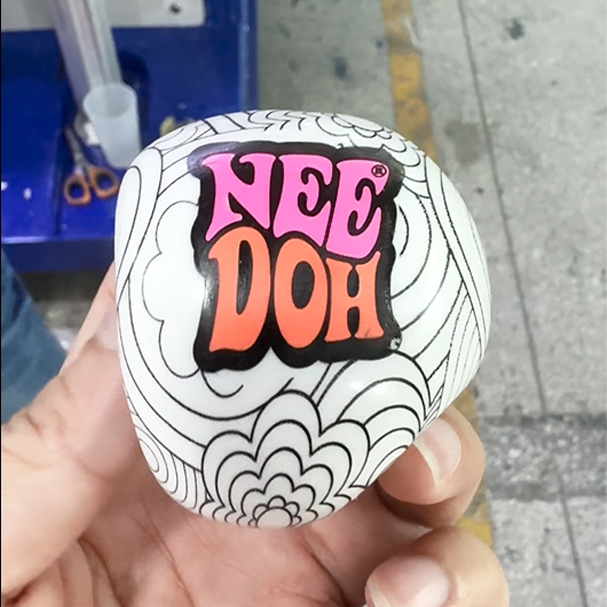

Your toys likely come in all sorts of interesting shapes - spherical, irregular, etc. These complex geometries require advanced printing techniques like curved surface printing, tamp printing, and heat transfer printing. These methods are crucial for achieving eye-catching decorative effects that enhance your toys' appeal and give you a competitive edge in the market.

We understand that the toy printing industry faces challenges with automation. Some printing processes are too complex to fully automate, which increases labor costs and reduces production efficiency. Additionally, existing automation equipment often can't adapt well to different materials and shapes, leading to frequent manual interventions and production disruptions.

Accurate color registration is vital for producing high-quality toys. However, achieving this can be challenging due to the complex shapes of toys, which can cause color misalignment. Ink batch variations can also lead to color mismatches. Furthermore, the precision and stability of printing equipment, including issues like wear and tear, can significantly impact color registration accuracy.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30