Jun 10, 2025

Labeling machines are an important part of modern packaging. They apply labels to products, containers, or packages in a fast and consistent way. Labeling machines are typically categorized based on their particular roles in the labeling process, which include printing, dispensing, and applying labels. Most labeling systems combine several of these processes into a single machine.There are two levels of automation for labeling machinery:One of the most common types is the automatic labeling machine. This type is designed for high-speed labeling with minimal human input. It can apply labels to bottles, jars, or boxes quickly and accurately. Automatic machines are often found on production lines where thousands of products are labeled daily. They are great for businesses that need speed and precision.

A semi-automatic labeling machine is another popular option, especially for small or medium-sized businesses. It requires an operator to load or position the item, but the machine applies the label. These machines are slower than fully automatic ones, but they offer flexibility and are more affordable. They’re often used in workshops or start-up factories where budgets and production volumes are lower.

Depending on the product shape, size, and label type, different labeling machines are used for different tasks. we will further explore various types of labeling equipment and their specific applications.One common type is the Round Surface Labeling Machine. As the name suggests, it’s built for products with round shapes—like bottles, jars, or tubes. These machines wrap the label around the curved surface smoothly and consistently. They’re often used in beverage, cosmetics, and chemical packaging. You can find both semi-automatic and automatic versions, depending on how fast and how often you need to label items.

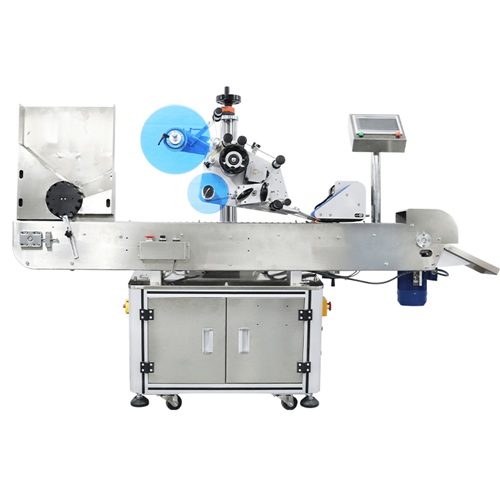

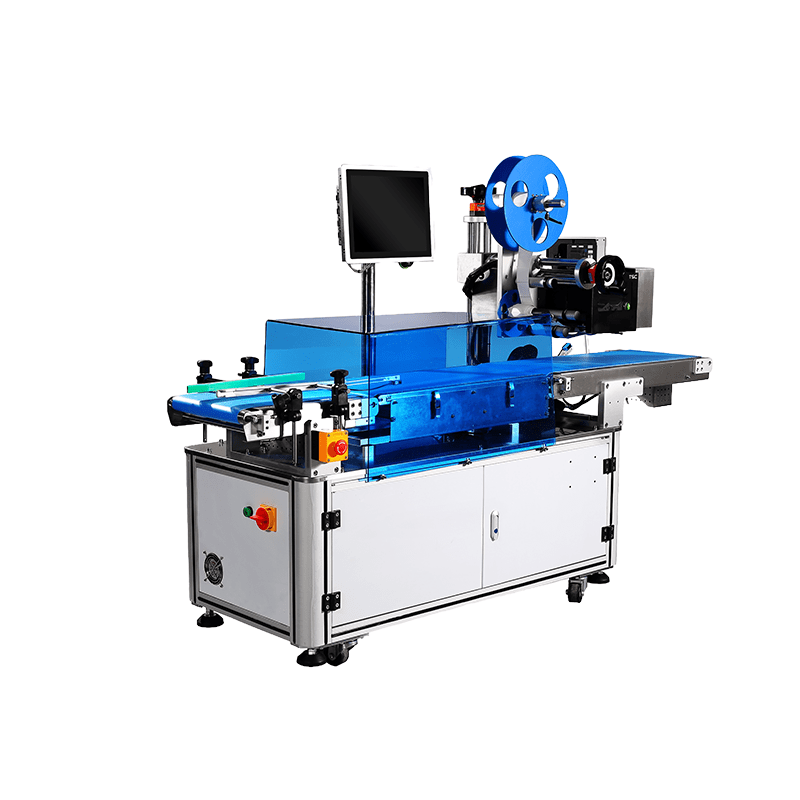

Another key machine is the Flat Surface Labeling Machine. This one is designed for products that have a flat front, top, or back—such as boxes, lids, cartons, or books. It ensures the label lays flat with no wrinkles or bubbles. This type is widely used in food trays, electronics packaging, and mailing systems. It’s a good choice if your product has a wide, even area where a label can be placed.

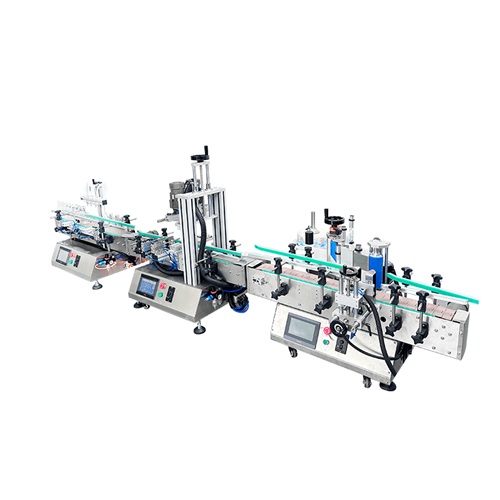

For products that need labeling in more than one place, there’s the Corner and Side Labeling Machine. These are used when a label must wrap from one side to another, such as across the edge of a box or container. This kind of machine is ideal for tamper-evident labels or promotional stickers. It’s commonly used in the pharmaceutical and personal care industries. This machine is also helpful when information must be seen from more than one angle.

In many industries like food, cosmetics, pharmaceuticals, and chemicals, labeling machines help improve efficiency, maintain quality, and meet regulatory standards. Choosing the right labeling machine depends on your product type, production speed, and budget.

Read More