Aug 14, 2025

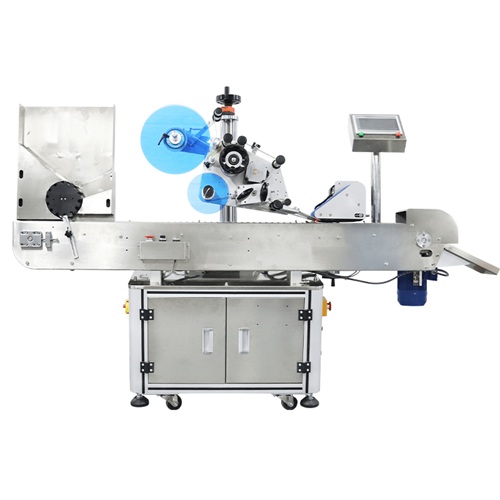

You can rely on an automatic labeling machine to handle many product shapes and sizes. Advanced features make this possible.

Integrated control panels let you adjust label placement quickly.

Optical fiber sensors and adjustable side guides help ensure every label fits perfectly.

Modular conveyors support smooth product flow for consistent product label application.

Automatic Labeling Machine Flexibility

Sensors and Guides

You rely on advanced sensors and guides to achieve precise product label application. An Automatic Labeling Machine uses a combination of electronic sensors, adjusting mechanisms, and guide devices to detect and adapt to different product shapes and sizes. The following table outlines the main components and their functions:

Component

Function

Label Sensor

Detects presence and location of the label to ensure correct timing and placement.

Product Sensor

Detects product presence and triggers labeling action as product moves on the line.

Adjusting Mechanism

Allows precise height, position, and angle adjustments to fit various product sizes/shapes.

Spacing Wheel

Ensures even spacing of products for accurate label application.

Guide Device

Uniformly guides products to the labeling position after spacing.

Adjusting Wheel

Supports adjustments for different product sizes and shapes.

You benefit from these features because they allow the automatic labeling machine to handle round, square, oval, flat, and irregular containers. WINNEO’s engineering team integrates high-quality sensors and adjustable guides into every label applicator, ensuring you achieve consistent product label placement. The control panel and PLC system let you set parameters for label speed and position, so you can quickly adapt to new product dimensions or shapes.

Modular Conveyors

Modular conveyors give you unmatched flexibility in your labeling process. You can tailor the conveyor system to fit your production line and product requirements. Here are some ways modular conveyors enhance your automatic labeling machine:

Modular components let you customize the system for different product lines and shapes.

Quick changeovers allow you to handle multiple SKUs and short production runs efficiently.

Upgrade-ready design means you can add conveyors or modules as your needs change.

Multi-label capability supports various labeling positions, such as front, back, top, wrap, or custom.

Flexible configurations fit into tight spaces and integrate with other packaging equipment.

Easy expansion and reconfiguration help you scale up or adjust your workflow with minimal downtime.

WINNEO’s automatic labeling machines use compact, space-saving conveyors that maintain smooth product flow and correct orientation. You reduce manual handling, lower labor costs, and protect product integrity during transfer. The modular design also supports seamless integration with inspection systems and other automation, so you keep your production line efficient and adaptable.

Product Label Accuracy

You expect high accuracy from your automatic labeling machine, and WINNEO delivers. Advanced sensor technology and precision motors ensure each label applicator places the product label exactly where you need it. Leading machines achieve label placement accuracy rates of up to 99%, so you minimize errors and reduce rework.

To prevent wrinkles and bubbles, WINNEO’s automatic labeling machines use wipe-down accessories like rollers or brushes. These components apply even pressure to the label as it adheres to the product, smoothing out air pockets and ensuring a flawless finish. Rotary label applicators rotate containers and use wipe-down systems to apply uniform pressure, even on curved or complex surfaces. Programmable Logic Control (PLC) systems let you fine-tune applicator settings and speeds, so you maintain consistent, high-quality product label application across all your products.

With WINNEO’s focus on precision, efficiency, and stability, you can trust your automatic labeling machine to deliver clean, accurate, and professional product label application every time.

Machine Types for Product Shapes

Flat Labeling Machine

You need a Flat Labeling Machine when your products have flat surfaces such as boxes, trays, cartons, or cards. These machines apply the label with precision, ensuring smooth adhesion and a professional finish. Flat labeling machines stand out because they handle flat bottles and packages with high accuracy. You can adjust these machines for different shapes, including oval, square, and rectangular bottles. This flexibility allows you to switch between various packaging formats without major downtime.

Flat labeling machines work well for single side, double side, and flat card applications.

You can use them for trays, clamshells, boxes, cartons, and cards.

Industries that rely on flat labeling machines include food and beverage, pharmaceuticals, cosmetics, chemicals, electronics, logistics, and consumer goods.

WINNEO’s fully automatic flat labeling systems offer advanced positioning and adjustable settings. You achieve high-precision product label placement, which is essential for branding and regulatory compliance. These machines support top and bottom labelers, making them ideal for packaging that requires multiple labels. You benefit from modular construction, which lets you expand or reconfigure your labeling stations as your business grows.

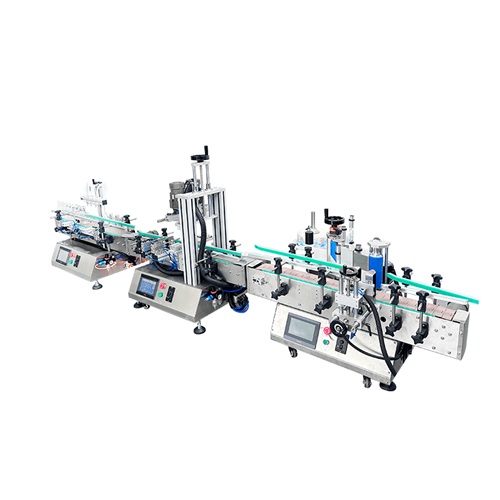

Bottle Labeling Machine

Bottle Labeling Machines give you the versatility to handle round, oval, square, and irregular bottle shapes. You can switch between different bottle types quickly, thanks to user-friendly controls and quick-change features. The table below shows how bottle labeling machines accommodate various bottle shapes and sizes:

Feature Category

Details

Versatility

Handles multiple bottle shapes and sizes including round, oval, and irregular shapes.

Changeover

Quick and easy changeover between different bottle types and sizes.

Specific Machine Types

Machines tailored for round shapes, square bottles, flat surfaces, polygon bottles, and corner labeling.

Labeling Mechanism

Supports various labeling methods (self-adhesive, wet glue, heat shrink) with high-precision label placement.

You can label bottles with diameters ranging from 20 mm to 150 mm, covering a wide range of packaging needs. WINNEO’s automatic round surface labeling machines use adaptive rollers and sensor feedback to ensure wrinkle-free label application. Servo motor control and photoelectric sensors allow you to adjust for different bottle sizes and label types with minimal downtime.

Pharmaceutical companies use bottle labeling machines for vials, syringes, and blister packs. Food and beverage manufacturers rely on these machines for bottles and cans. Cosmetics brands use them for jars and tubes. You benefit from multi-label application, serialization, and barcode support, which are essential for compliance and traceability.

Food Labeling Machines

Food labeling machines play a critical role in the food and beverage industry. You need these machines to apply labels to bottles, jars, cans, trays, and clamshells. Food labeling machines offer several features that make them suitable for diverse packaging types:

Self-adhesive labelers provide vibrant and seamless label application for bottles, jars, and cans.

Sleeve labelers apply full-body wrap-around labels, enhancing shelf appeal for beverage containers.

Shrink sleeve labelers use heat to tightly fit labels around products, improving durability and appearance.

Compatibility with various container shapes and sizes lets you handle different packaging without frequent reconfiguration.

Modular and customizable systems give you flexibility and scalability for changing production volumes.

Precision sensors ensure accurate and consistent label placement, reducing errors and waste.

Seamless integration with existing production lines maintains high-speed operations.

Compliance support features help you meet industry regulations and maintain quality standards.

Automation reduces manual errors and boosts productivity.

Quick switching between products or packaging types supports agility in a fast-paced market.

Scalability allows you to expand capabilities as your business grows.

WINNEO’s food labeling machines deliver reliable performance for trays, cartons, bottles, and cans. You can meet FDA regulations for nutritional content, ingredient lists, allergen declarations, and expiration dates. These machines also support branding and barcodes, which are vital for product identification and consumer trust.

Cosmetics labeling machines share some features with food labeling machines but focus more on safety reporting, allergen transparency, and professional-use designations. You must disclose fragrance allergens and provide clear contact information for reporting adverse events. WINNEO’s machines help you comply with MoCRA requirements while maintaining high-quality product label application.

You should consider several factors when choosing a labeling machine for your product shape:

Match the machine to your product type and label specifications.

Evaluate production volume and speed requirements.

Ensure compatibility with label size, shape, and material.

Look for ease of operation and maintenance.

Consider scalability and integration with other automated equipment.

Balance cost with long-term efficiency and support.

WINNEO’s product range includes fully automatic flat labeling systems, automatic round surface labeling machines, and specialized food labeling machines. You gain access to advanced technology, modular design, and dedicated customer support, ensuring your labeling process remains efficient and adaptable across industries such as pharmaceuticals, food and beverage, cosmetics, chemicals, and electronics.

You achieve versatility and high performance with automatic labeling machines. You select flat or bottle machines to match your label requirements. You meet your labeling needs with precision. WINNEO offers label solutions for every industry. You trust WINNEO to handle any label, any shape, and any size. Your labeling needs always find the right label machine. You rely on WINNEO for label accuracy, label speed, and label consistency. You see label quality improve with every label application. You experience label reliability and label stability. You choose WINNEO for label innovation. You maximize label efficiency. You simplify label changeovers. You optimize label placement. You ensure label compliance. You elevate your label process with WINNEO.

Read More