Recently, Winneo's Technical Director, Owen, personally visited a partner factory for a two-week on-site visit. The goal of this trip was clear: to get down to the production line, learn the proofing process firsthand, gain a deep understanding of production details, and lead the comprehensive upgrade and development of factory inspection standards for pad printing machine and labeling machine, laying a solid foundation for delivering more reliable and stable equipment to global customers.

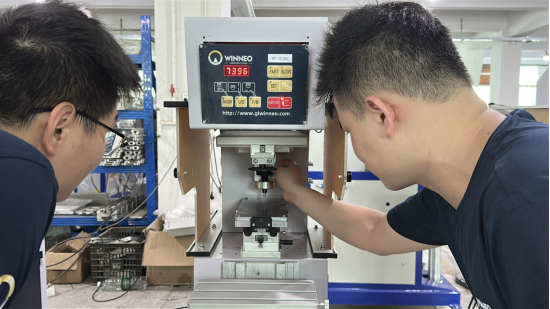

Owen understands that superior technical support stems from a deep understanding of customers' actual production scenarios. On the factory floor, under the guidance of experienced technicians, he participated in the entire process of basic proofing. The technicians patiently and meticulously explained every step of the pad printing machine proofing process. Owen listened attentively, writing down the key points and operation sequence in his hands. When it was his turn to practice, Owen followed the previously recorded steps and operated step by step: installing parts, starting the scraper, adjusting the position, installing the rubber head, placing the product...

But the process was not smooth. Sometimes the scraper wasn't evenly squeegeeing the ink, sometimes the pad wasn't picking up ink completely, and sometimes the printed pattern was slightly off. Whenever these issues arose, the technicians around him could always spot the problem at a glance. They would either demonstrate in person or point to specific components. With their precise prompts and hands-on guidance, seemingly intractable challenges were easily resolved. Owen felt the subtle changes brought about by each adjustment, and his skills grew more proficient. Through this immersive learning and practice, Owen not only mastered the proofing process but also gained a deeper understanding of the importance of experience and feel in equipment operation, as well as the meticulous and dedicated craftsmanship of the technicians.

After mastering the equipment, Owen, based on practical experience and customer feedback, began revising the factory inspection standards for labeling and pad printing machines. He refined requirements for operational stability, repeatability, and inspection of key components, and incorporated issues discovered during proofing into preventive inspections.

After completing the initial draft, Owen immediately discussed it with the factory's quality inspection team leader and shipping personnel. They optimized some inspection methods based on actual production line operations and provided practical suggestions. Owen then consulted with the company's business department, focusing on common customer pain points. Based on this, he strengthened acceptance requirements for equipment cleanliness, accuracy of accompanying documents, and secure affixed safety labels.

Combining technical practices, production line experience, and customer perspectives, the new factory inspection standards for labeling machine and pad printing machine were finalized. Their core value lies in providing clear, measurable specifications to improve equipment reliability and consistency before shipment, reducing commissioning issues for customers.

During this factory visit, Winneo's Technical Director, Owen, through in-depth hands-on learning and close collaboration with multiple stakeholders, not only deepened his understanding of core processes but also successfully promoted the refinement of key standards: pad printing machine inspection standards were refined and upgraded, while labeling machine inspection standards were systematically established. These two rigorous, quantitative, and actionable new standards will significantly improve the reliability and consistency of Winneo equipment before shipment, effectively reducing customer commissioning time and ensuring a smoother out-of-the-box experience. Winneo will continue to refine its standards based on practical experience to deliver trusted, high-quality equipment to customers worldwide.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30