Dec 19, 2025

Comparing Productivity Features of Pad Printing Machines

Explore the productivity differences between single and multi color pad printing machines.

Features

WINNEO Single Color Pad Printing Machine

WINNEO Multi Color Pad Printing Machine

Printing Speed

High speed for single color jobs.

Up to 1000 pieces per hour.

Setup Time

Quick setup for single ink.

Longer setup for multiple inks.

Workflow Complexity

Simple and straightforward process.

Complex with multiple steps.

Job Suitability

Best for simple designs.

Ideal for intricate, multi-color designs.

Training Requirements

Low training complexity.

Moderate to high training needed.

Maintenance Needs

Standard maintenance tasks.

More frequent checks required.

Cost Efficiency

Lower operating costs for simple jobs.

Higher upfront cost but efficient for complex jobs.

Color Capability

Single color printing only.

Prints up to six colors.

You will achieve higher productivity with a multi color pad printing machine when your jobs involve complex designs or require several colors. If your printing tasks are simple and need only one color, a single color machine often works faster and more efficiently. Productivity depends on job type, how quickly you set up the machine, and your skill as an operator. Market trends show that multi color machines dominate industries with high demand for customization, while single color machines are growing in popularity among small businesses. The choice between each semi-automatic pad printing machine reflects your specific production needs and goals.

Key Takeaways

· Choose a single color pad printing machine for simple jobs. It offers faster setup and higher efficiency for high-volume tasks.

· Opt for a multi color pad printing machine when handling complex designs. It allows printing multiple colors in one cycle, boosting productivity.

· Consider changeover and setup time. Single color machines require less time for job changes, while multi color machines save time on large batches.

· Evaluate your most common printing tasks. Match the machine type to your job complexity and color requirements for optimal results.

· Invest in operator training. Skilled operators enhance productivity by reducing errors and maintaining a smooth workflow.

Productivity in Semi-automatic Pad Printing Machines

Workflow and Speed Comparison

When you compare single color and multi color pad printing machines, you notice differences in how each machine handles workflow and speed. Single color pad printing machines usually offer a straightforward process. You load your substrate, set the ink, and start printing. The operator manages each step, which keeps the workflow simple and efficient for jobs that require only one color.

Multi color pad printing machines introduce more steps into the workflow. You need to align each color, adjust the pads, and monitor the sequence of prints. These machines often use turntables or shuttles to move the substrate between different color stations. This setup allows you to print complex designs in one cycle, which increases speed for multi-color jobs. You can reach speeds of up to 1000 pieces per hour with advanced multi color pad printing machines, especially when printing several colors at once.

Machine Type

Workflow Complexity

Speed for Single Color Jobs

Speed for Multi Color Jobs

Single Color

Simple

High

Low

Multi Color

Complex

Moderate

High

If you print only one color, single color pad printing machines work faster because you avoid extra steps. If your job needs multiple colors, multi color pad printing machines save time by printing all colors in one pass. You should choose the machine that matches your job requirements to maximize productivity.

Tip: For high-volume jobs with simple designs, single color pad printing machines help you finish faster. For detailed, multi-color prints, multi color pad printing machines boost your output.

Changeover and Setup Time

Changeover and setup time play a major role in overall productivity. When you switch from one job to another, you need to change inks, adjust fixtures, and set up the machine for the new design. The time you spend on these tasks affects how many items you can print in a day.

You benefit from pad printing machines that offer features like closed ink cups and adjustable fixtures. These features help you change jobs quickly and reduce downtime. Here are some ways changeover time impacts productivity:

· Quick changeovers reduce downtime between print jobs, enhancing overall production efficiency.

· Machines with features like closed ink cups and adjustable fixtures facilitate faster changeovers.

· Reduced setup time leads to less printing time lost, directly impacting productivity.

Single color pad printing machines often require less setup time because you only need to prepare one ink and pad. You can switch jobs quickly, which helps you keep your production line moving. Multi color pad printing machines need more setup time since you must prepare several inks and align multiple pads. However, if you print many multi-color jobs in a row, you save time by not having to run each color separately.

You should consider how often you change jobs and the complexity of your prints. If you run frequent changeovers, single color pad printing machines may offer higher productivity. If you print large batches of multi-color designs, multi color pad printing machines help you work more efficiently.

Key Factors: Number of Colors and Job Complexity

Impact of Number of Colors on Productivity

You need to consider the number of colors in your design when you choose a pad printing machine. If you print with only one color, you can finish jobs quickly with a single color pad printing machine. You load the substrate, set the ink, and print in one pass. This process works well for simple logos, serial numbers, or basic graphics.

When your job requires multiple colors, you face more steps. Multi color pad printing machines let you print several colors in a single sequence. You do not need to batch products for each color. This feature saves you time and reduces labor costs. You can handle complex designs more efficiently.

The table below shows how each machine type handles complex jobs:

Feature

Multi-Color Machines

Single-Color Machines

Printing Capability

Multiple colors in a single or few passes

Requires multiple passes for multi-color

Efficiency for Complex Jobs

More efficient, saves time and labor

Slower for complex jobs

Design Complexity

More complex with advanced control systems

Simpler design

If you print detailed graphics or need high-resolution images with several colors, multi color pad printing machines help you achieve better productivity. You save time because you do not need to run the same item through the machine for each color. You also lower your work in process inventory, which helps you manage your production line more effectively.

Tip: If your business prints products with more than one color, you should consider a multi color pad printing machine to boost efficiency and reduce labor.

Application Suitability by Job Type

You must match your pad printing machine to the type of job you handle most often. Single color pad printing machines work best for simple tasks. You can use them for marking medical devices, printing serial numbers on industrial equipment, or adding logos to consumer electronics. These jobs need clear, durable prints but do not require complex color schemes.

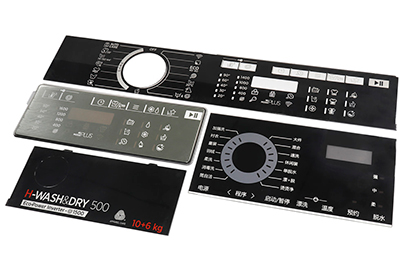

Multi color pad printing machines suit jobs that demand intricate designs and multiple colors. You find these machines in industries like cosmetics, toys, and automotive. For example, a beauty-tech start-up needed three-color, high-resolution prints on unique applicators. Multi color machines made this possible in one sequence, saving time and ensuring consistent quality.

You see multi color pad printing machines used for:

· Advertising gadgets

· Plastic and glass packaging

· Automotive dashboards and control knobs

· Medical and pharmaceutical products

· Household appliances

Single color pad printing machines excel at:

· Marking instruments and syringes in medical fields

· Branding on smartphones and laptops

· Serial numbers and safety warnings on heavy machinery

· Efficient marking on injection-molded and 3D-printed parts

You should look at your most common jobs and decide which machine fits your needs. If you print simple, high-volume items, single color machines offer speed and reliability. If you print complex, multi-color designs, multi color machines deliver better results and higher productivity.

Note: The right machine depends on your job complexity and the number of colors you need. You can improve your workflow and reduce costs by choosing the best fit for your production line.

Operator Skill and Maintenance in Pad Printing Machines

Training Requirements

You play a key role in the productivity of semi-automatic pad printing machines. Your skill level determines how quickly and accurately you complete each job. You must align items by hand, keep the workflow moving, and check every print for quality. If you have experience and know the machine well, you can boost both speed and print quality.

Single color pad printing machines usually require less training. You learn basic setup, ink handling, and substrate alignment. You master the process quickly and start printing with confidence. Multi color pad printing machines need more advanced skills. You must understand color registration, pad alignment, and sequence control. You spend more time learning how to manage multiple colors and adjust the machine for complex jobs.

Machine Type

Training Complexity

Key Skills Needed

Single Color

Low

Basic alignment, ink setup

Multi Color

Moderate to High

Color registration, sequencing, pad adjustment

Tip: You can improve productivity by investing in operator training. Skilled operators reduce errors and keep the workflow smooth.

Maintenance and Downtime

Regular maintenance keeps your pad printing machines running smoothly. You face similar maintenance tasks with both single color and multi color machines, but multi color machines may require extra attention due to their complexity.

Common maintenance issues include:

· Ink adhesion problems

· Managing the life of consumables

· Routine maintenance checks

You should follow these steps to minimize downtime:

· Wipe the pad and plate clean after each job

· Inspect for ink residue on all surfaces

· Check that the substrate fixture stays aligned

· Lubricate moving parts regularly

If you maintain your machine well, you avoid unexpected breakdowns and keep production on schedule. Multi color machines may need more frequent checks because they have more moving parts and color stations. You should set a regular maintenance schedule and train your team to spot issues early.

Note: Consistent maintenance helps you extend the life of your pad printing machine and ensures high-quality prints every time.

Choosing the Right Pad Printing Machine

Production Volume and Cost

You need to look at your production volume before you choose between pad printing machines. If you run high-volume jobs with simple designs, single color pad printing machines often give you faster results and lower operating costs. These machines use less ink and require fewer adjustments, which helps you save money over time. You also spend less on training because operators learn to use single color machines quickly.

Multi color pad printing machines work best when you print complex designs or need several colors on each item. These machines handle larger batches with intricate graphics, which increases your output for multi-color jobs. You may pay more upfront for multi color machines, but you gain efficiency when you print products that need multiple colors. You also reduce labor costs because you do not need to run each item through the machine several times.

Tip: If your business prints thousands of items with detailed designs, multi color pad printing machines help you keep costs low and productivity high.

Decision Guide for Machine Selection

You should compare several factors before you select pad printing machines for your operation. The table below shows key decision criteria:

Decision Criteria

Description

Complexity of Color

Evaluate the complexity of color requirements for your printing needs.

Printing Speed

Consider the speed of production and how it affects overall efficiency.

Ease of Use

Assess how user-friendly the machine is for operators.

Cost Considerations

Analyze the cost implications of each machine type for your budget.

You need to match your machine to your job type. If you print simple, single-color items, single color pad printing machines offer speed and reliability. If you print multi-color graphics, multi color pad printing machines deliver better results and save time. You should also think about operator skill and maintenance needs. Specialized pad printing machines can help you meet unique requirements, such as printing on curved surfaces or using special inks.

· Make a list of your most common jobs.

· Decide how many colors you need for each job.

· Estimate your monthly production volume.

· Compare the cost of each machine type.

· Ask your team about training and maintenance needs.

Note: Specialized pad printing machines give you more flexibility if you handle custom projects or unusual materials.

You improve your workflow and reduce costs when you choose the right pad printing machines for your business.

WINNEO Pad Printing Machines Overview

Semi-automatic Standard Pad Printing Machine Features

You find that WINNEO offers a Semi-automatic Standard Pad Printing Machine built for precision and stability. This pad printing machine uses a thickened steel plate for the body, which gives you reliable operation during high-volume tasks. The high-quality pad printing machines from WINNEO use CNC-machined components. These parts help you achieve consistent quality and accuracy. You benefit from original FESTO/SMC brand components, which keep failure rates low and reduce downtime. WINNEO includes a full-chain quality control system. This system ensures every pad printing machine meets strict standards before delivery. You receive 24/7 after-sales support, so you can solve any issues quickly. The intuitive controls and adjustable settings make this semi-automatic pad printing machine easy for you to use.

Single Color Pad Printing Machine Advantages

You gain several advantages when you choose a WINNEO Single Color Pad Printing Machine for semi-automatic operations. The machine delivers high printing efficiency, so you complete jobs quickly. You operate the machine easily with a microelectronic keyboard controller. You print on flat, curved, and irregular surfaces, which gives you versatility. The table below summarizes the main advantages:

Advantage

Description

High Printing Efficiency

The machines are designed for optimal performance, ensuring quick and effective printing.

Easy Operation

Features like a microelectronic keyboard controller simplify the operation process.

Versatility

Capable of printing on various surfaces including flat, curved, and irregular shapes.

You also benefit from WINNEO’s focus on quality. The robust construction and precision components help you maintain consistent results. You find that the semi-automatic pad printing machine reduces setup time and keeps your workflow smooth.

Multi Color Pad Printing Machine Advantages

You see that the WINNEO Multi Color Pad Printing Machine offers unique benefits for complex jobs. This pad printing machine prints up to six colors in one cycle, which boosts your productivity. You use a microcomputer control system to manage functions and actions. The independent rubber head lets you adjust stroke and speed for each color. You position the ink base and workbench with X, Y, and R axis adjustments. The machine uses a turntable or shuttle for stable operation. You reach speeds up to 1000 pieces per hour, which helps you handle large batches.

WINNEO pad printing machines address maintenance and downtime challenges with strong build quality and precision components. You use calibration tools to keep performance high. You integrate the pad printing machine with your existing systems easily. You access spare parts and technical service quickly, which minimizes downtime. WINNEO provides training programs and warranty terms for peace of mind.

Aspect

Description

Build Quality

Ensures durability and reduces the frequency of repairs.

Precision of Components

Enhances the accuracy of printing, minimizing errors that could lead to downtime.

Calibration Tools

Availability of tools for regular calibration helps maintain optimal performance.

Integration Capabilities

Compatibility with existing systems reduces the need for extensive modifications.

After-Sales Support

Access to spare parts and technical service ensures quick resolution of issues, minimizing downtime.

Training Programs

Provides operators with the knowledge to effectively use and maintain the machines.

Warranty Terms

Offers peace of mind regarding repairs and replacements, further reducing potential downtime.

You improve your workflow and achieve high-quality results when you select the right WINNEO semi-automatic pad printing machine for your needs. You compare the Single Color Pad Printing Machine and Multi Color Pad Printing Machine to find the best fit for your production goals.

You achieve higher productivity with multi color pad printing machines for complex, multi-color jobs. Single color machines work best for simple, high-frequency changeovers. Your choice depends on job complexity, number of colors, and production volume. Use the table below to assess your needs:

Factor

Description

Number of Colors

Multi-color machines print more colors at once.

Frequency of Changeovers

Single color machines reduce downtime for frequent changes.

Production Volume

Multi-color machines boost efficiency for large batches.

Specific Requirements

Match machine features to your product needs.

· Balance speed and print quality.

· Consider material compatibility and surface challenges.

· Analyze cost versus performance.

Consult suppliers or experts for tailored recommendations.

FAQ

What is the main difference between single color and multi color pad printing machines?

You use single color machines for simple prints. Multi color machines handle complex designs with several colors in one cycle.

Machine Type

Best For

Single Color

Simple jobs

Multi Color

Complex graphics

Which machine offers faster setup for frequent job changes?

You set up single color machines faster. You change ink and pad quickly. Multi color machines need more time for color alignment and pad adjustments.

Tip: Choose single color machines for frequent changeovers.

Can you print on curved or irregular surfaces with both machines?

You print on flat, curved, or irregular surfaces with both machine types. WINNEO pad printing machines offer adjustable settings for different shapes.

· Flat surfaces

· Curved surfaces

· Irregular surfaces

Which machine is better for high-volume production with detailed designs?

You achieve higher productivity with multi color pad printing machines for high-volume, multi-color jobs. You print several colors in one pass, saving time and labor.

Multi color machines boost efficiency for complex, large batches.

Do operator skills affect productivity for both machine types?

You need basic skills for single color machines. Multi color machines require advanced skills for color registration and pad alignment.

Machine Type

Skill Level Needed

Single Color

Basic

Multi Color

Advanced

Read More