Nov 10, 2025

Take a moment to walk through any retail aisle. What separates a product that looks premium, trustworthy, and professional from one that looks cheap or untrustworthy? Often, the answer is right on the surface: the label.

We tend to think of product labels as simple identifiers or marketing flourishes. But in the world of manufacturing and packaging, a label is a critical component. Its accuracy—or lack thereof—has profound, cascading effects on your brand perception, your legal standing, and ultimately, your bottom line.

Many businesses, especially those scaling up, underestimate the true cost of "good enough" labeling. A slightly crooked label here, a small wrinkle there... what’s the big deal?

As it turns out, it's a very big deal. Let's explore why label accuracy is far more than just an aesthetic concern.

1. The High Cost of Inaccuracy: Legal and Compliance Nightmares

In many industries, the label isn't just a suggestion; it's a legally mandated contract with the consumer.

Pharmaceuticals & Nutraceuticals: An incorrect ingredient list, a misplaced dosage instruction, or an illegible expiration date can lead to serious health risks, triggering massive recalls, hefty fines from bodies like the FDA, and devastating lawsuits.

Food & Beverage: Allergen warnings are non-negotiable. If a label is applied incorrectly and obscures this information, your company is exposed to immense liability.

Chemicals & Industrial Products: Hazard warnings and safety instructions must be clear, present, and correctly oriented. A peeling or misapplied label that hides a "Flammable" warning is a disaster waiting to happen.

In these regulated environments, inaccuracy isn't a branding problem; it's a full-blown compliance crisis.

2. Brand Erosion: You Get One First Impression

Your product’s packaging is its "suit of armor." A high-quality product hidden inside packaging with a wrinkled, bubbled, or crooked label sends a powerful, negative message to the consumer:

"If they can't get the outside of the bottle right, can I trust what's inside?"

This is especially true for products competing in a premium space. Cosmetics, craft spirits, gourmet foods, and wellness products rely on a perception of quality. A flawed label instantly shatters that perception, demoting your product from "premium" to "discount" in the customer's mind. Consistent, perfect label placement builds brand trust and reinforces the quality you worked so hard to create.

3. Supply Chain & Logistical Chaos

Modern logistics run on data, and on a physical product, that data lives in the barcode, QR code, or batch code. What happens when labels are applied inconsistently?

Unscannable Barcodes: If a label is wrinkled, wrapped too far around a curve, or placed on a seam, scanners at warehouses, retailer distribution centers, and point-of-sale (POS) systems will fail.

Retailer Rejection: Major retailers have strict supplier guidelines (compliance). Shipments with poorly applied labels or unscannable barcodes are frequently rejected, leading to chargebacks, returned inventory, and strained partner relationships.

Traceability Failure: If a batch code is illegible, your ability to execute a quick, surgical recall is compromised. You may be forced to recall a much larger batch of products than necessary, multiplying your costs.

4. The Path to Precision: Beyond Manual Application

For a startup, labeling bottles by hand in a small batch might be feasible. But as you scale, this process becomes a major bottleneck and a primary source of inconsistency.

This is where automation becomes a strategic necessity. Manual labeling is slow, labor-intensive, and inherently inconsistent. No matter how skilled your team, they cannot replicate the speed and flawless consistency of a machine, hour after hour.

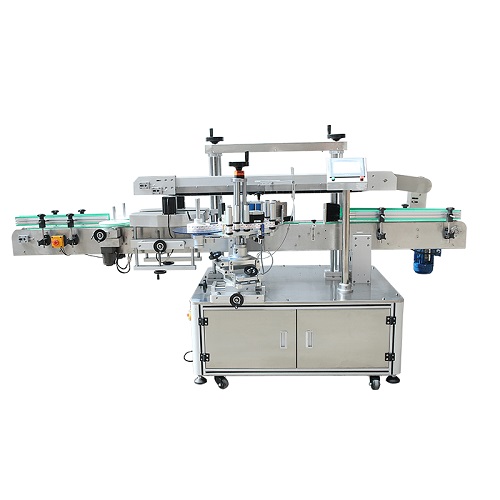

Investing in automated systems, such as Round Bottle Labeling Machines, is the single most effective way to eliminate these variables. These machines are engineered to handle the specific challenge of applying labels to a curved surface. They ensure that every single label is applied at the exact same height, with the same orientation, and with perfect tension to prevent bubbles and wrinkles.

5. The True ROI of Accurate Labeling Technology

It's easy to look at automated equipment as a capital expense. Instead, it should be viewed as an investment with a massive return on investment (ROI), generated by:

Drastically Reduced Labor Costs: Reallocating skilled employees from the monotonous task of labeling to higher-value roles.

Elimination of Rework: How much time and money is spent peeling off bad labels and re-applying them? An automated system gets it right the first time.

Increased Throughput: A high-speed Automatic Bottle Label Applicator can process hundreds of products per minute, dramatically increasing your production capacity.

Brand Protection: Preserving the premium image you've built, ensuring positive first impressions on the shelf.

Risk Mitigation: Ensuring compliance and avoiding the catastrophic costs of recalls and legal action.

Achieving true, replicable accuracy isn't a luxury; it's a core pillar of a scalable, professional operation. The right Labeling Equipment for Round Containers is specifically engineered for this precision, using sensors and precise mechanics to deliver flawless results that manual labor simply cannot match.

Conclusion: Don't Let Your Label Be Your Downfall

A product label is your handshake with the customer, your compliance certificate, and your logistical passport. Treating it as an afterthought is a costly mistake.

The accuracy of your label directly reflects the quality of your brand and the integrity of your operation. In today's competitive market, there is no room for error.

Ready to Eliminate Labeling Errors for Good?

If you're tired of battling inconsistent labels, high rework costs, and the risks of non-compliance, it's time to automate.

Our advanced labeling solutions are designed for precision, speed, and reliability. Contact our team today for a free consultation to discuss your product's specific needs and discover how the right automation can transform your production line.

Read More