Features of this product:

High-Precision Machining

Adopts advanced CNC grinding technology, ensuring the blade edge runs concentrically with the ring body. This minimizes uneven ink scraping during transfer, guaranteeing consistent print quality even for fine patterns.

Durable Material Selection

Crafted from ceramic or tungsten carbide, resisting wear from repeated contact with ink and substrates (e.g., plastic, metal). Extends service life by 30% compared to standard carbon steel.

Optimized Blade Edge Design

The blade edge features a micro-beveled structure (angle adjustable: 30°/45°/60°) to adapt to different ink viscosities (water-based, solvent-based, UV-curable) and substrate surfaces (smooth/rough). Prevents ink buildup or excessive scraping, reducing rework rates.

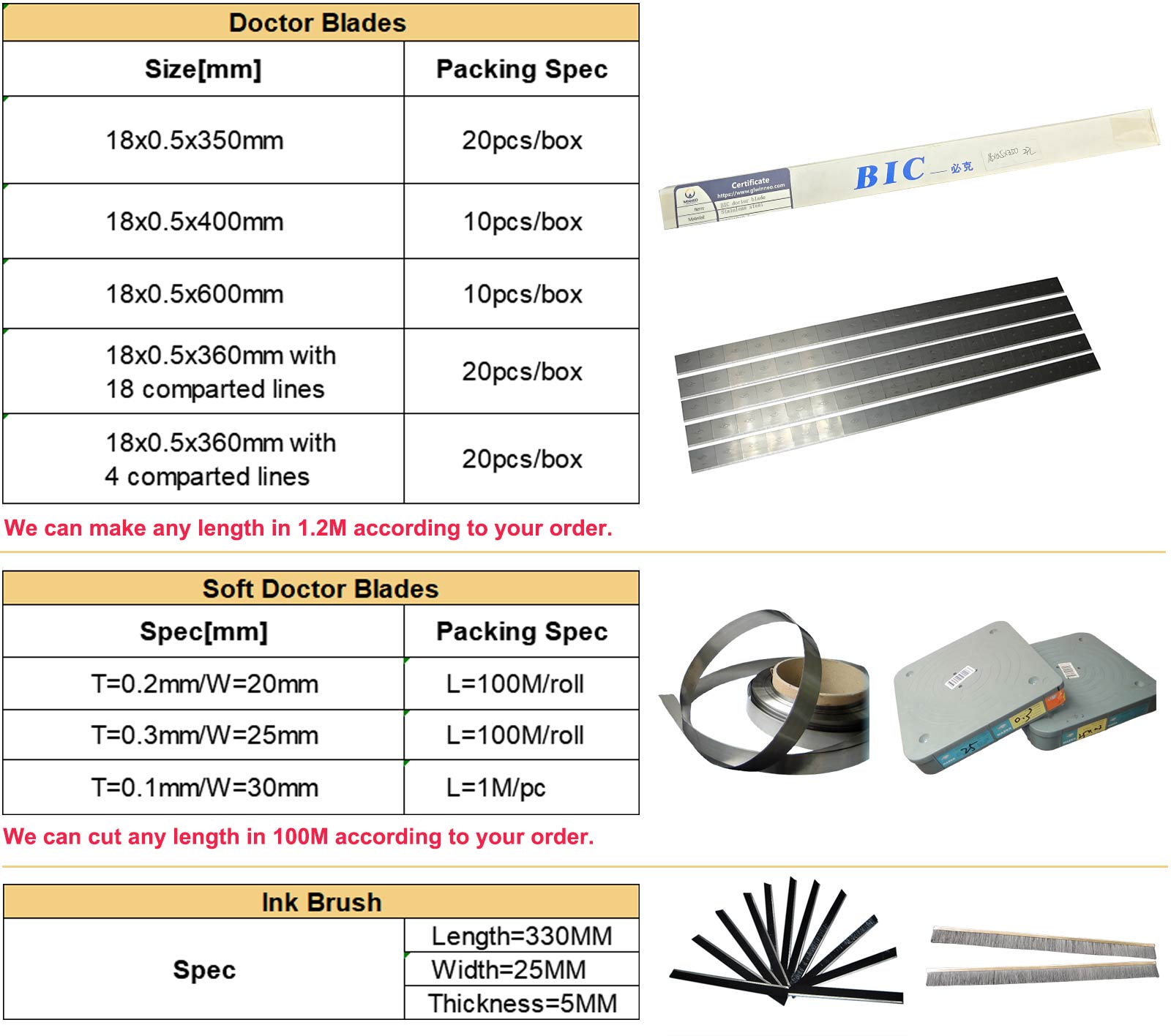

WINNEO Pad Printing Doctor Blade

WINNEO Pad Printing Doctor Blade

Customer Concerns

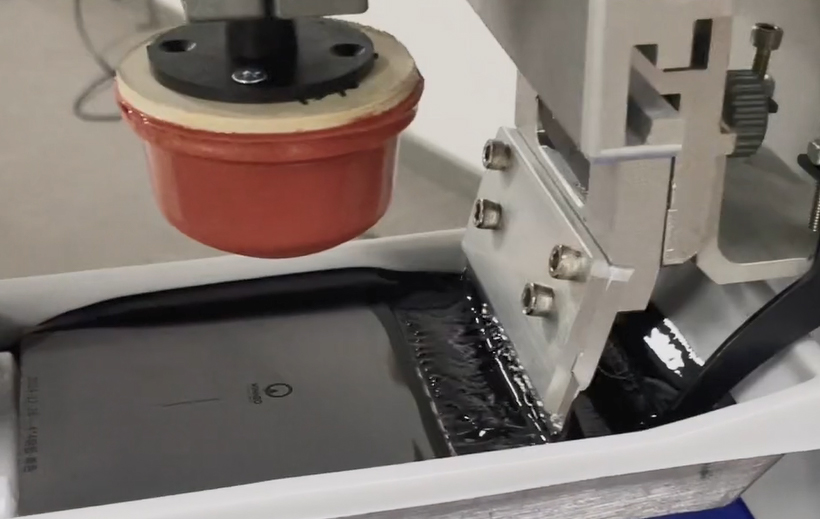

Ink leakage: There are many factors that lead to ink leakage during the printing process. The factors of the doctor blade are usually the sealing and integrity of the doctor blade. This causes ink to leak from the sealing between the doctor blade and the plate or pad, resulting in ink leakage.

Not durable: Inappropriate selection of raw materials and flawed manufacturing processes are the two major reasons for the lack of durability in Pad Printing Doctor Blades.

Not scratch-resistant: Substandard wear resistance of raw materials is the main reason for the poor wear resistance of the doctor blade. Unable to withstand high-frequency ink scraping and returning, it wears quickly, leading to frequent replacements, increased costs and disrupted production.

WINNEO Standard of Pad Printing Ring

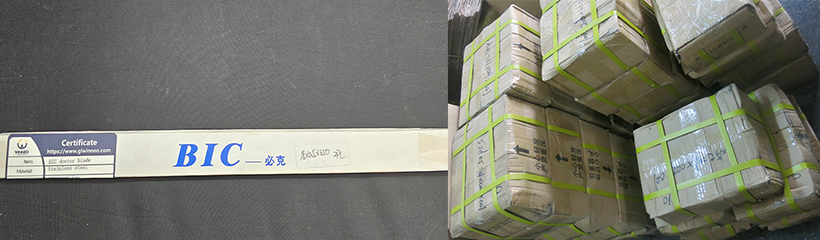

WINNEO Safety Packaging for Pad Printing Doctor Blades.

WINNEO After-sales Standards

Efficient response within 24 hours, with dedicated personnel assigned for follow-up. Lifetime one-on-one online technical support.

Customers Recommend

WINNEO Pad Printing Doctor Blades are highly praised by customers.

FAQ

1.Why does the Pad Printing Doctor blade wear out so quickly?

This could be due to factors such as excessive blade hardness, poor blade quality, or excessive pressure during printing. Adjustments should be made promptly.

2.Why isn't the ink scraper clean?

There are usually many reasons for this. It could be that the blade is installed unevenly, with improper pressure or at an inappropriate angle. These issues need to be investigated and addressed one by one.

3.Why are the pad printing patterns blurry?

It may be caused by uneven installation of the doctor blade, inappropriate blade material, improper hardness and curvature of the pad, or too fast drying speed of the ink.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30