Features of this product:

Matching Hardness: Heat-treated to HRC52+/-1, meeting the hardness requirements for pad printing steel sheets.

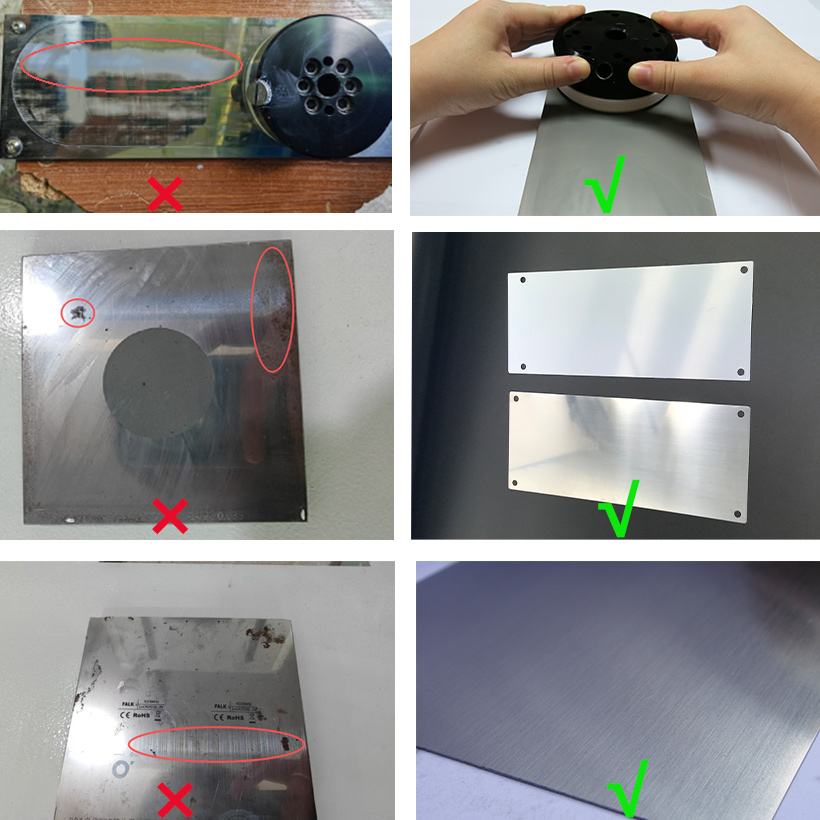

Stable Printing Effect: Meets standards for finish and flatness, free of scratches, impurities and blowholes, with no ink leakage.

Long Life: Base material with qualified element content, meeting standards and featuring strong durability.

Low Cost: Direct supply from source factory, with more competitive wholesale prices.

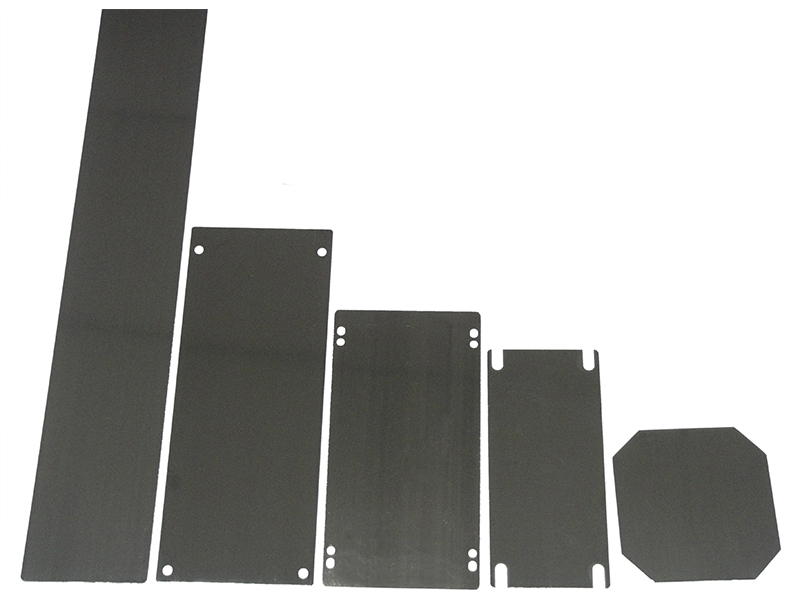

WINNEO Pad Printing Thin Cliché

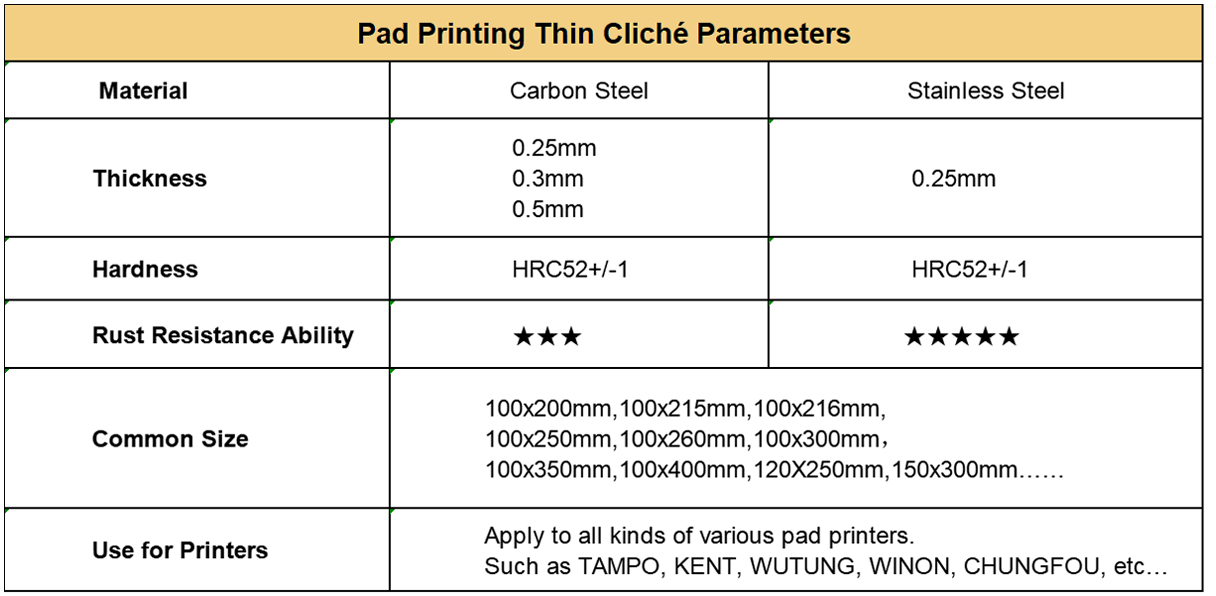

WINNEO Pad Printing Thin Cliché Parameter

Customer Concerns

Ink leakage: There are many factors that lead to oil leakage during the printing process. The factors of the steel plate are usually reflected in the surface treatment, resulting in insufficient flatness and smoothness of the steel plate.

Rusting: There are many factors that cause steel plates to rust. The factors of steel plates are usually reflected in the raw materials. If qualified rust-resistant base materials are not used, the steel plates will be easily rusted during use.

Not scratch-resistant: The lack of scratch resistance of pad printing steel plates is usually due to inadequate heat treatment. If this process is not done well, the steel plates will not reach the required hardness and it will be difficult to achieve the expected number of prints.

WINNEO Standard of Pad Printing Thin Cliché

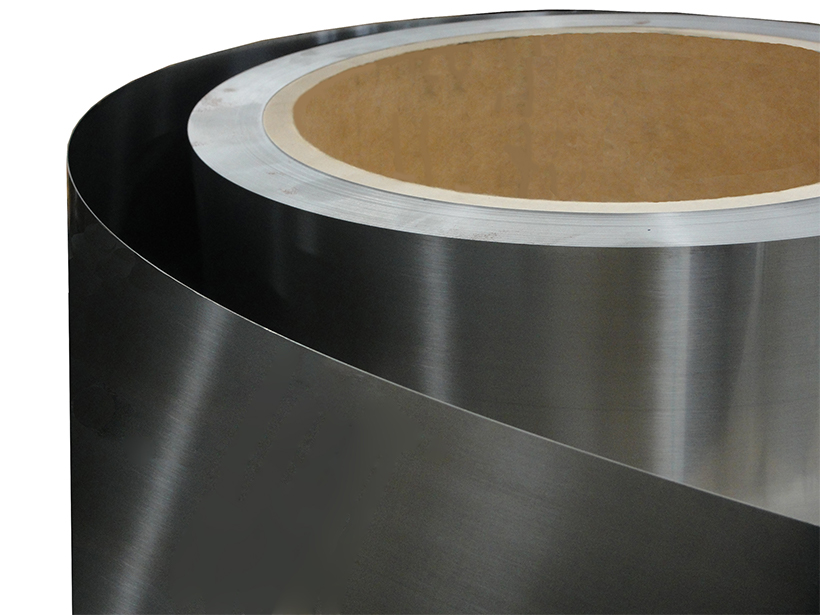

Pad Printing Thin Cliché Raw Material

WINNEO Pad Printing Thin Cliché Raw Material Component Standards

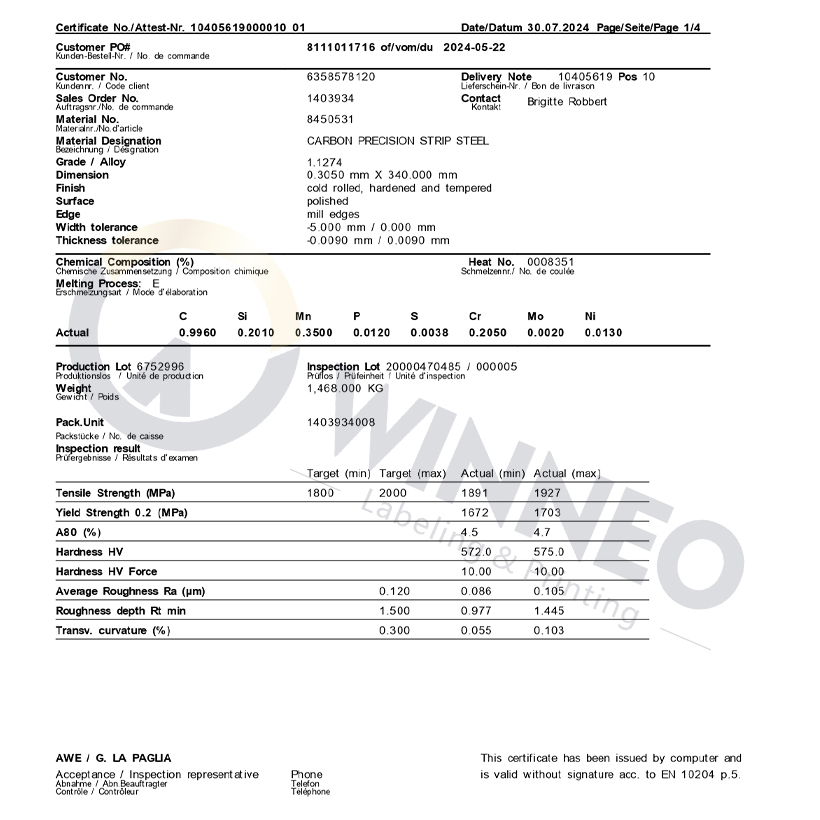

This is the original composition test report for the raw materials used in WINNEO Pad Printing Thin Cliché. This report proves that the raw materials used in our Pad Printing Thin Cliché meet quality standards. Qualified raw materials ensure that subsequent steel plate manufacturing complies with relevant standards.

WINNEO Pad Printing Thin Cliché QC

WINNEO Packaging Standards

WINNEO Pad Printing Thin Clichés are packaged in a plastic inner packaging, a cardboard box, and a reinforced wooden crate. This triple packaging ensures product stability, eliminating the need to worry about damage during transport. WINNEO clear packaging labels make it easy to quickly verify order information.

WINNEO After-sales Standards

Efficient response within 24 hours, with dedicated personnel assigned for follow-up. Lifetime one-on-one online technical support.

If You Need

We can make the special size thin steel plates with holes or not according to your request!

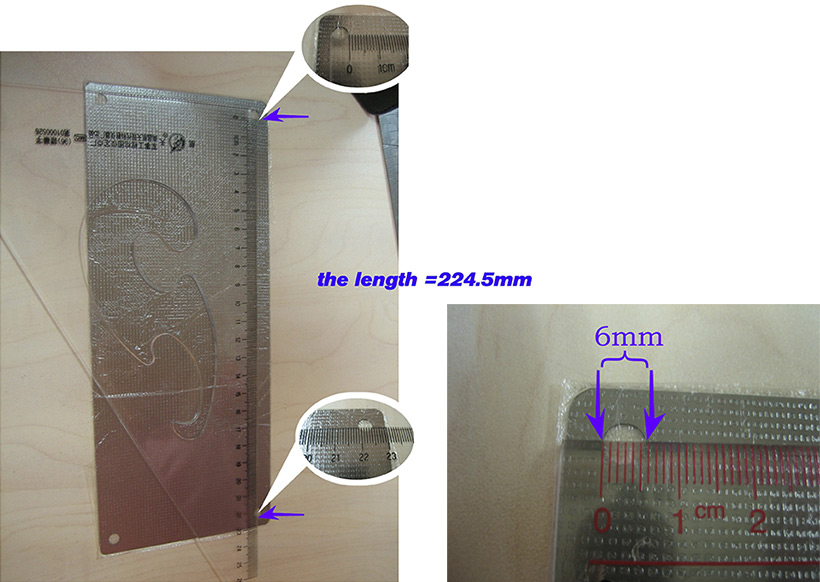

Measuring these data is essential for punching holes in Pad Printing Thin Cliché.

Measuring these data is essential for punching holes in Pad Printing Thin Cliché.

Customers Recommend

WINNEO Pad Printing Plates are highly praised by customers.

FAQ

1.What is the service life of a pad printing plate?

Its service life is affected by factors such as substrate material, usage frequency, and printing environment; specifically, it needs to be determined based on actual usage conditions.

2.How to choose the right pad printing plate specifications?

Selection depends on the printing equipment, the size and shape of the printing pattern, and production requirements. We recommend providing specific printed products, printing positions, and pattern files, and our professional pre-sales team will offer accurate support.

3.Will all pad printing plates rust? How to extend the rust resistance duration and service life of pad printing plates?

1. Rusting is inevitable for pad printing plates made of non-chromium steel or non-stainless steel.

2. You can extend their rust resistance duration and service life in the following ways:

① Thoroughly clean and dry the plates before and after printing; when printing is paused for more than 1 hour, apply a thin layer of anti-rust oil on the plate surface or cover it with anti-rust film/paper for temporary rust protection.

② Wrap each plate with anti-rust paper, or seal it in a bag after applying anti-rust oil; ensure transportation and storage conditions are "dry, light-proof, corrosion-free, and at room temperature".

③ Prioritize purchasing plates from formal manufacturers, as they offer better guarantees for raw material quality and quality control systems.

4.Can you customize steel plates of special specifications?

Yes, we can customize pad printing thick plates and thin plates according to your specific requirements, including thickness, size and pattern.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30