Features of this product:

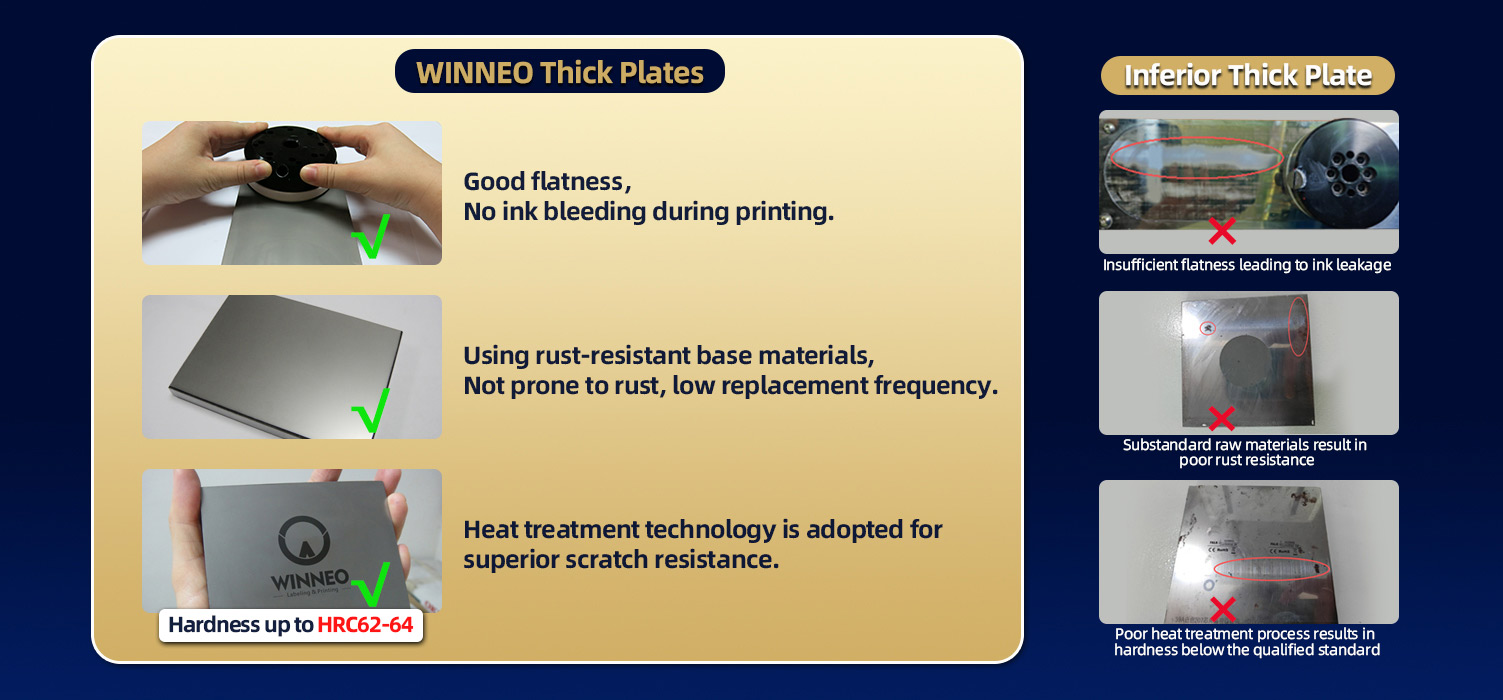

High-quality base material, high hardness ensures long-lasting and durable printing

Premium chromium-rich raw materials are selected. Through sophisticated heat treatment, the hardness reaches HRC63±1, guaranteeing the printing plate remains sturdy as new even after prolonged use. It boasts a long service life, reducing the cost of frequent steel plate replacement and offering greater convenience.

High flatness and smooth surface

Through precision machining, the printing plate surface achieves exceptional flatness and smoothness. It ensures sharper, more delicate patterns during printing, with uniform ink distribution and no leakage or blurring. Every print meets professional standards, delivering flawless finished products.

Excellent corrosion resistance

It possesses outstanding rust and corrosion resistance, maintaining reliable performance in humid, acid-alkaline or other complex environments. While extending the service life, it also simplifies maintenance for greater convenience, ensuring stable and smooth production.

Customization available

To meet diverse customer needs, we offer pad printing steel plates in various sizes and thicknesses, including specifications like 3×4, 4×4, and 3×6. Of course, customization is also available based on your specific requirements. No matter how complex the printing task is, WINNEO can provide the most suitable solution.

WINNEO pad printing plate video

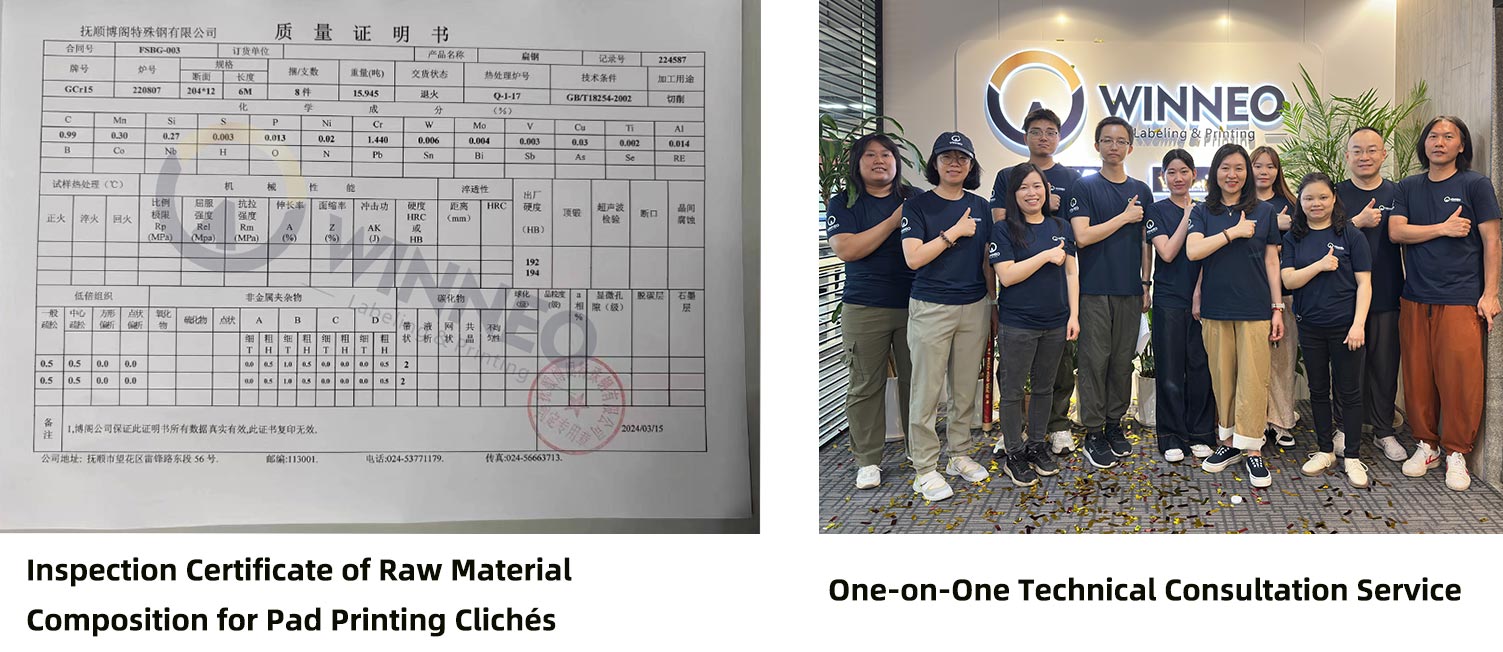

This is the thick plate for pad printing produced by WINNEO. From raw materials to processing and final delivery, we dedicate 100% attention to detail, aiming solely to earn your satisfaction.

Why choose WINNEO pad printing steel plates?

WINNEO pad printing thick cliché parameter

Any special size thick steel plate can be made according to your order!

How to choose a suitable pad printing cliché?

Special clichés can be customized in WINNEO!

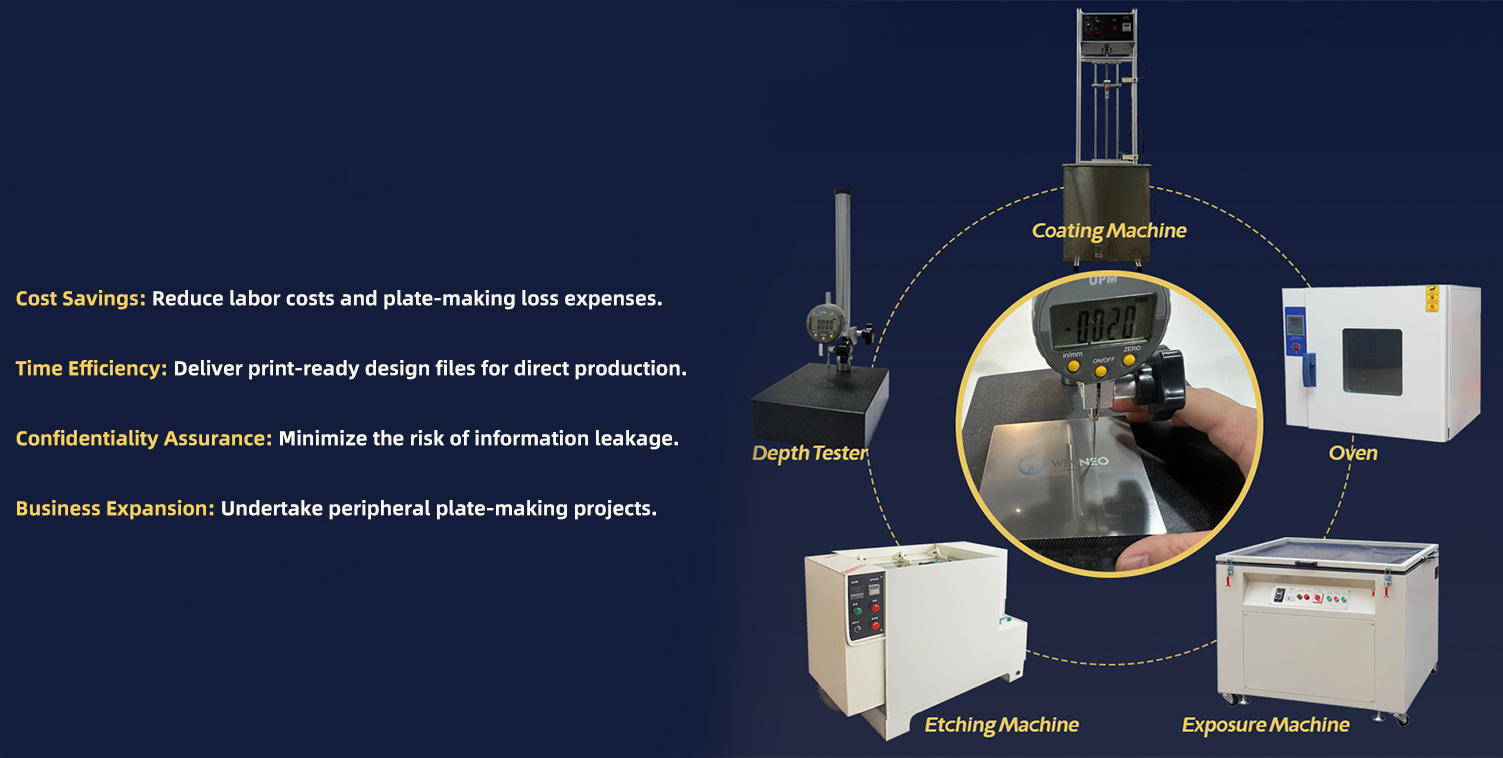

WINNEO plate-making system

Satisfactory printing results often come from the perfect match between pad printing technology and plate-making materials. With nearly 20 years of experience in the pad printing industry, we are well acquainted with the special requirements for pattern and plate production. The WINNEO team has transformed professional plate-making knowledge and experience into a set of operable and valuable services to help you achieve the following goals:

Contact Us! Have a Clichés Manufacturing Workshop of Your Own!

Pre-sales testing & after-sales tech support

WINNEO is Committed to Resolving 99% of After-Sales Issues with Quality Products.

Safety shippment

Triple-layer packaging ensures product stability and safety during transportation, WINNEO delivers high-quality products to customer.

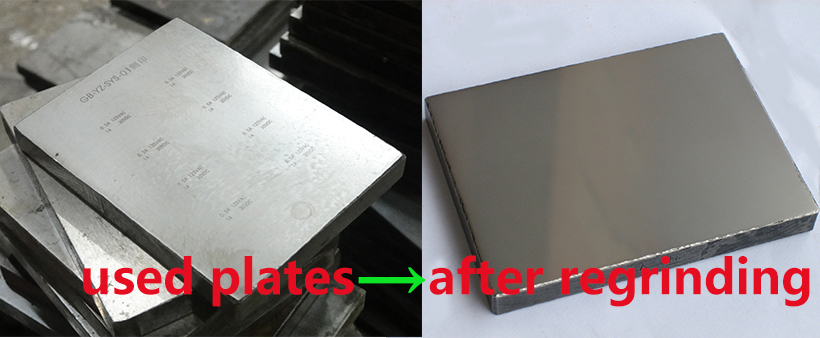

WINNEO used plates regrinding tips

A good-quality cliché plate, should have stable heat treatment hardness within 0.3mm thickness of its surface, and we usually etched the image on the cliché plate for 0.02~0.04mm at one time, so please do not discard the cliché after first use, it can be reground by the professional manufacturers, and then it can be used again.

WINNEO ADVICE: The common steel (such as the GCr15 or 2510# steel material) cliché plates can be reground and reuse 2 or 3 times, and the Chrome steel cliché plates (such as the D2), you can reuse 5 times or more.

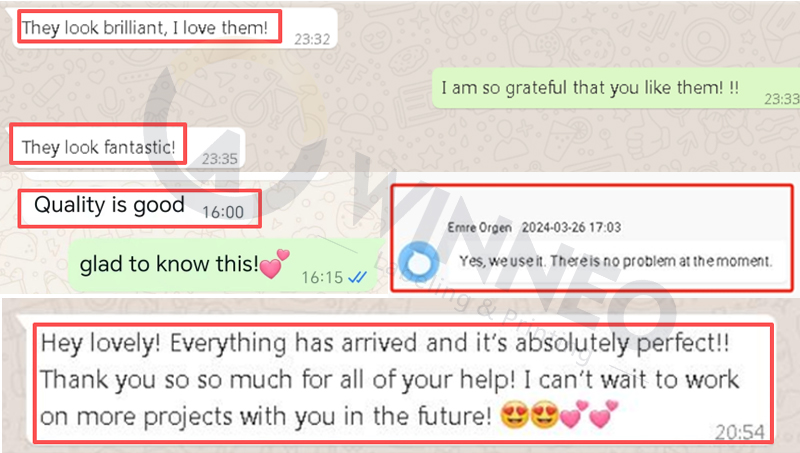

Customer feedback

WINNEO has been deeply engaged in the pad printing industry for years and earned widespread acclaim. Thank you for our customers' recognition!

FAQ

1.What is the life of pad printing plates?

The service life is affected by many factors such as material, frequency of use, printing environment, etc. Generally speaking, the number of printing times for chrome steel plates can reach hundreds of thousands, and for oil steel plates it can reach more than 50,000 times, but the specific service life needs to be determined according to actual use.

2.How to choose the appropriate pad printing plate specifications?

The selection should be based on the printing equipment, the size and shape of the printed pattern, and production requirements.

3.What should I do if the pad printing thick plate is rusted?

If the steel plate or sheet is rusted, it may affect the printing quality. Minor rust can be treated by grinding, polishing, etc.

4.Can you customize steel plates and sheets to special specifications?

Yes, we can customize pad printing thick plates and thin plates to your specific specifications, including thickness, size, and pattern.

5.What is the price of thick plates and thin plates?

Prices vary depending on factors such as material, specifications, and processing technology. Stainless steel plates are more expensive, and prices for plates with special specifications or high precision requirements will also increase accordingly.

6.Can you customize steel plates and sheets to special specifications?

Yes, we can customize pad printing thick plates and thin plates to your specific specifications, including thickness, size, and pattern.

7.How about your hardness and materials?

Our plates are made of high-quality alloy steel with stable hardness, which can ensure that the edges of the patterns will not wear or deform during long-term printing. They are especially suitable for high-frequency and high-precision pad printing scenarios.

8.How about the surface finish?

The surface is precisely polished with high smoothness, ink adheres evenly, is not easy to rust, and has good batch consistency.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30