Features of this product:

Precise transfer printing

The surface is fine, which can accurately absorb ink and completely transfer it to the workpiece, ensuring clear patterns.

Wide adaptability

Can be customized into different shapes and sizes, suitable for curved and special-shaped workpieces, meeting various printing needs.

Anti-static rubber head optional

Low surface resistance, reducing dust adsorption and avoiding pattern defects caused by static electricity during printing.

Solvent corrosion resistance

Can withstand various ink solvents, not easy to swell or harden, adapting to complex printing environments.

WINNEO pad printing pad

The standard printing pads of WINNEO can meet almost all application requirements, with a variety of specifications available.

We can also customize special-shaped printing pads according to specific application requirements. Machines and consumables integrate seamlessly to deliver optimal solutions.

4 reasons to choose WINNEO

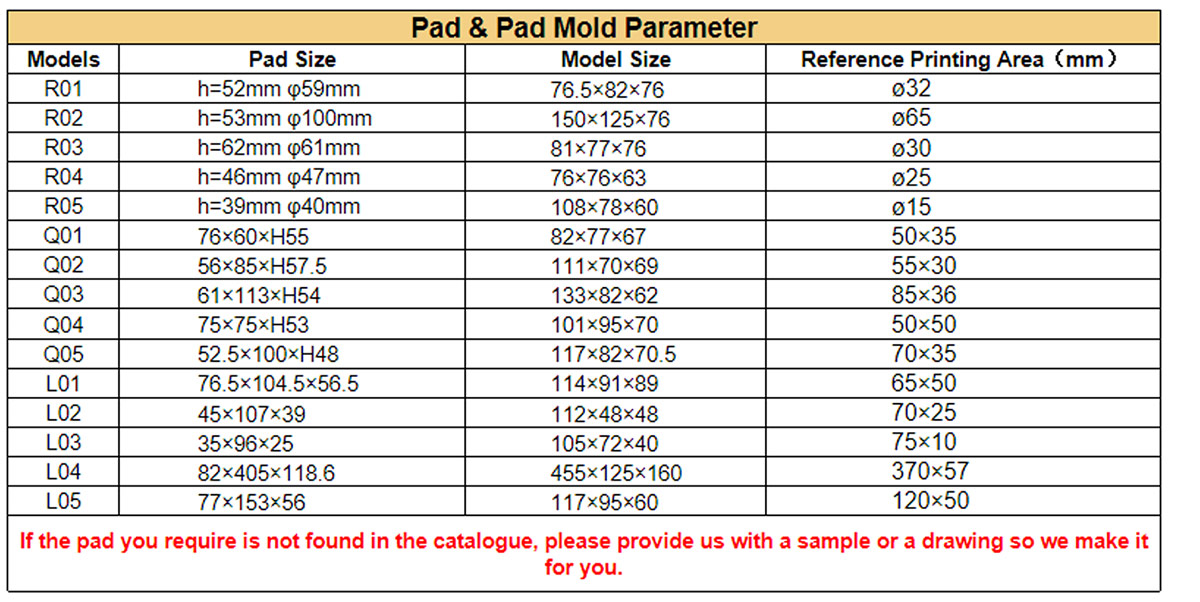

WINNEO pad printing pad parameter

How to choose the pad printing pad?

Standard Printing Pads

With nearly 20 years of experience in the pad printing industry, WINNEO manages an extensive pad printing rubber pad database. We offer a large selection of printing pads for a wide range of applications.

The size of the pad printing pad depends on the image that needs to be printed on the product. WINNEO will be happy to support and advise you in choosing the right printing pad.

Standard plan is not your solution?

Customized Printing Pads

We make printing pads in our own factory. If no suitable pad shape is available, we will create a printing pad perfectly matched to the substrate you want to print. WINNEO will take your printing results to the next level.

Printing applications sensitive to static electricity

Antistatic Printing Pads

Antistatic rubber heads can effectively reduce the adsorption of dust and impurities, ensure the clarity and integrity of printed patterns, and guarantee a smooth printing process.

1、Effectively resolves issues such as pinholes, pitting, or blurriness in printed patterns caused by static electricity.

2、Antistatic printing pads are mainly used for various products requiring high precision, high speed, and high cleanliness—such as mobile phone casings, keys, lenses, bottle caps, chip resistors, capacitors, and all types of high-precision electronic products.

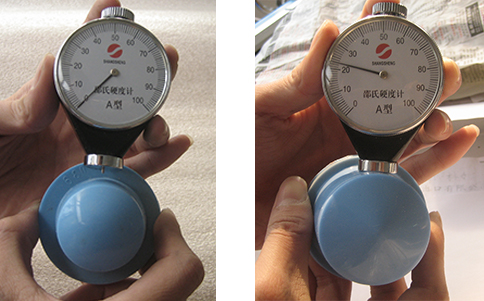

Hardness Rating of Pad

Select the right pad hardness level for your optimal printing results.

• Soft (S):5-8 Shore A ——Best for large curved surfaces or wide-area printing

• Medium (M):10-15 Shore A ——Universal hardness for most applications

• Hard (H): >15 Shore A——Ideal for complex shapes & high-precision small patterns

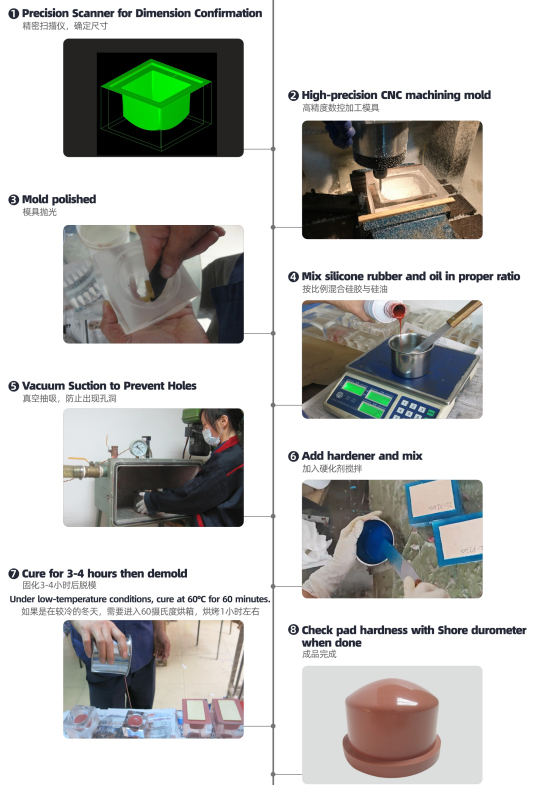

Production Process

WINNEO provides customized pad & mold design solutions.

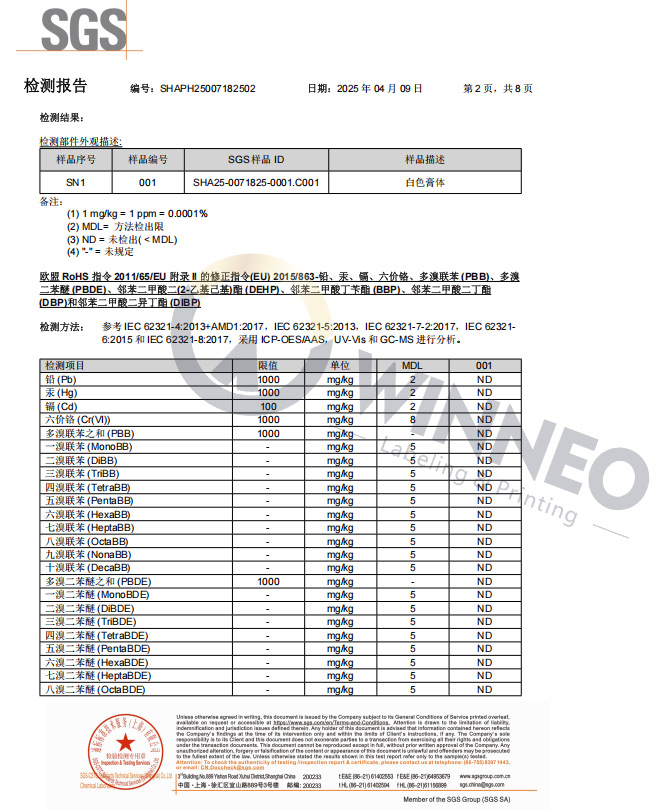

Raw Material Validation

We offer raw materials with SGS-approved certifications. Ensure the products meets high standards in performance and durability, reducing replacement frequency and maintenance costs.

Safety Shipment

Triple-layer packaging ensures product stability and safety during transportation,

WINNEO delivers high-quality products to customer.

Customers Recommend

WINNEO Pad Printing Pads are highly praised by customers.

FAQ

1. Why won't the pad printing pad pick up ink?

Mostly because the hardness is too high, preventing full contact with the printing plate to absorb ink; it may also be that oil stains or impurities on the surface hinder ink adhesion.

2. Why are the printed patterns unclear?

Inappropriate hardness (hard pads for fine patterns), uneven or damaged surface, leading to uneven ink absorption/transfer.

3. Why is the pad printing pad not durable?

Silicone contains impurities, excessive silicone oil damages the structure, or the size doesn't match the pattern (using a small pad for large patterns), making it prone to cracking and aging.

4. Why are there bubbles in printing?

Too flat shape, incorrect curvature, or the center point aligning directly with the pattern, causing air to be trapped; surface damage can also cause this.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30