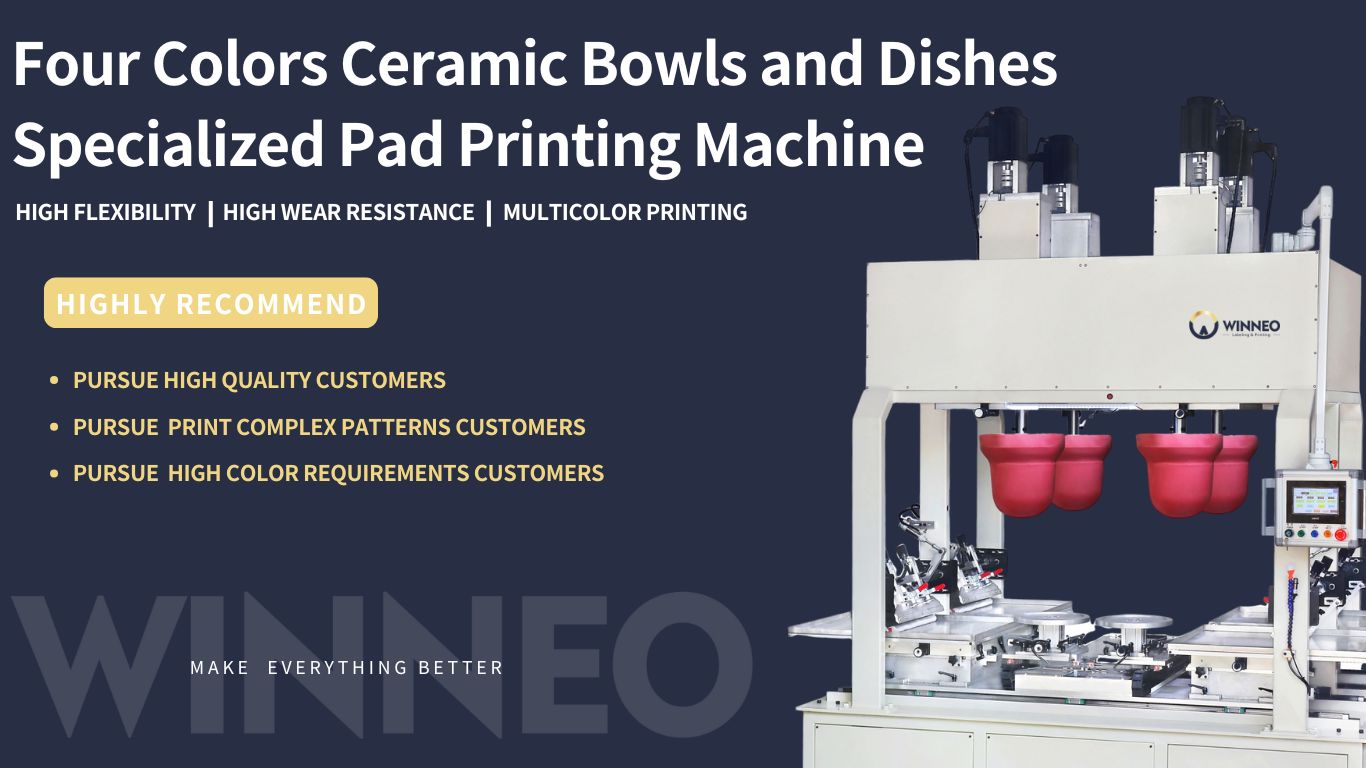

Features of this machine:

1. Specially design of up spraying and apply to the clichés plate-making for pad printing.

2. With the time-controlled and thermostat system, ensure accurate etching depth.

3. The spray nozzles and the plate holder staggered swing make higher etching precision.

Technical Parameters

| Model | WP-CEREMIC-4 |

| Maximum printing area | 320X320mm |

| Maximum steel sheet size | 400X400mm |

| Body size | 1950X1600X2700mm |

| Technical Parameters | |

| Model | WP-CEREMIC-4 |

| Maximum printing area | 320X320mm |

| Maximum steel sheet size | 400X400mm |

| Body size | 1950X1600X2700mm |

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30