Features of this product:

Closed Cup Design

Closed ink cup design, save the ink and environmental.

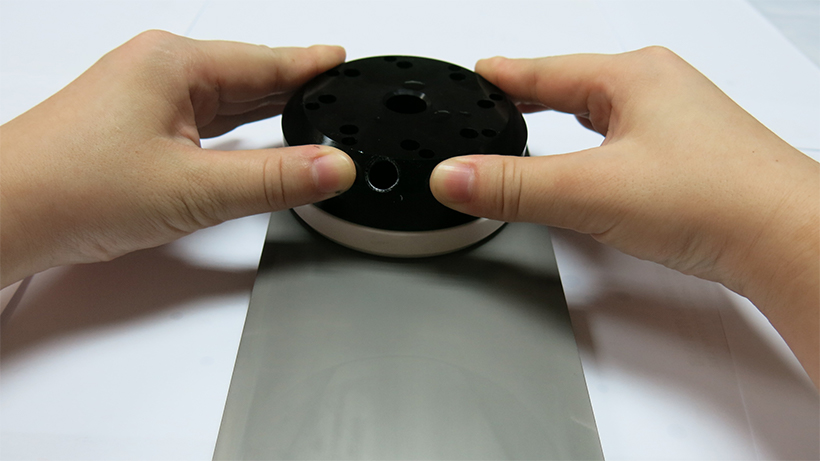

Convenient Ink Refilling

Easy to add ink.

Easy Assembly & Disassembly

Easy to assemble and disassemble, with strong adaptability.

Corrosion-resistant, Sturdy & Non-deformable Cup Body

The corrosion-resistant, sturdy & non-deformable cup body can withstand long-term contact with various inks, avoiding damage from chemical erosion.

WINNEO Pad Printing Ink Cup

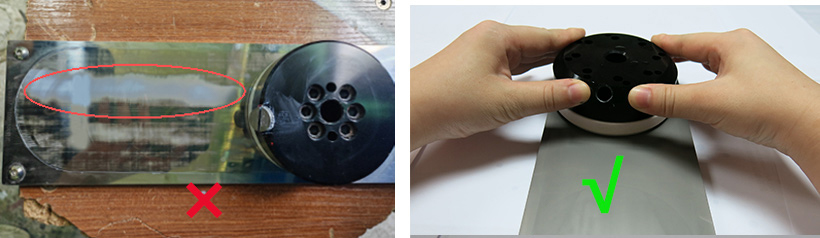

WINNEO Pad Printing Ink Cup Parameter

We can make any special spec ink cups and rings according to your order.

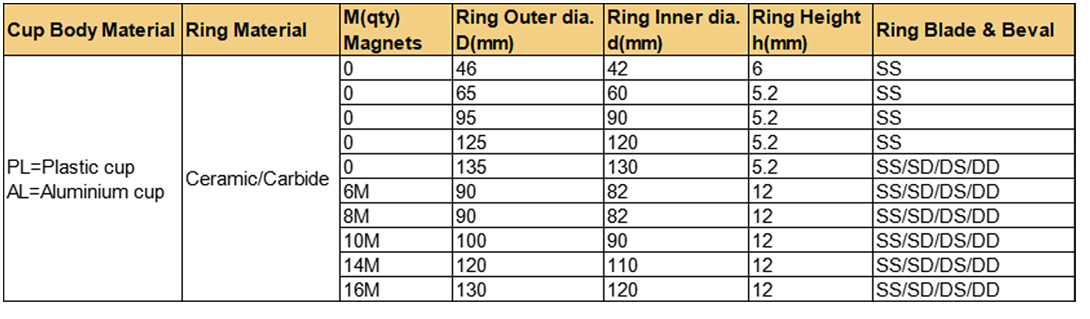

· The oil cup itself has poor sealing and is prone to oil leakage.

· The structure of the oil cup makes it difficult to clean.

· The built-in magnet of the oil cup is easily damaged and its

magnetism decreases.

WINNEO Standard of Pad Printing Ink Cup

We offer a wide range of ink cup types to perfectly match your pad printing machine.

A complete oil cup consists of the following four parts.

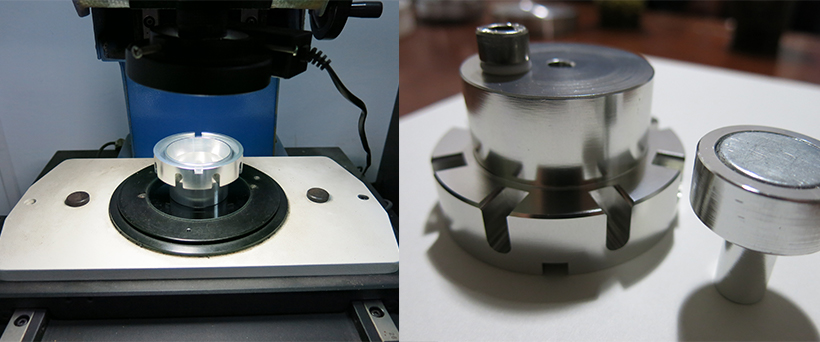

Precision machining ensures the ink cup is well sealed.

WINNEO Pad Printing Ink Cup QC Testing.

WINNEO safe packaging ensures that the oil cup is intact during transportation.

WINNEO After-sales Standards

Efficient response within 24 hours, with dedicated personnel assigned for follow-up. Lifetime one-on-one online technical support.

Customers Recommend

WINNEO Pad Printing Ink Cups are highly praised by customers.

FAQ

1.How to choose a suitable ink cup?

Match the pad printer model; select material based on ink properties (viscosity, corrosiveness); check if the ring is sharp and wear-resistant.

2.What's the easiest way to clean an ink cup?

Clean it after work to prevent ink from drying and hardening; soak it in a dedicated solvent, and disassemble detachable models first before wiping.

3.What to do if the ink cup leaks?

First check the seal ring—replace it if aged or damaged; then adjust ink viscosity (too thick easily causes overflow); finally check if the doctor blade/ring is worn.

4.What if the ink cup magnet doesn't hold firmly?

Clean ink and impurities off the magnet surface; replace the magnet directly if its magnetism weakens.

5.Why is ink not scraped clean?

First check the doctor blade (wear, gaps); then check if the steel plate is flat or has scratches; finally increase the ink cup pressure.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30