Features of this product:

Durable Material Selection

Premium raw materials are carefully selected. Defective raw materials are rejected through professional testing. Quenching and tempering heat treatment, together with rust removal pretreatment, are applied to optimize mechanical properties, laying a solid foundation for the cutter ring’s durability and corrosion resistance.

High-Precision Machining

Leveraging imported CNC lathes and grinders, strict tolerance control is achieved. We follow the standardized procedures of rough turning, precision grinding, chamfering and deburring to ensure stable dimensional and structural accuracy.

Complete & rigorous QC system

A complete inspection system combining 100% full inspection and sampling inspection is implemented. Finished products undergo comprehensive testing covering dimensions, hardness and other key parameters. Sampled products are subjected to simulated working condition tests. Qualified products are rust-proof packaged with a unique traceability code to guarantee zero defects before delivery.

WINNEO Pad Printing Rings

Our pad printing ring is made of high-quality raw materials, ensuring high hardness, wear and corrosion resistance, long service life and stable performance.We offer a variety of sizes to meet the requirements of different equipment. Meanwhile, we also provide personalized customization services, enabling us to tailor-make exclusive rings according to your specific needs, helping you continuously improve production efficiency and product quality.

3 Reasons to choose WINNEO

How to choose the suitable ring

Carbide Rings: The material has high hardness and is not easy to crack, which greatly reduces the frequency of replacement and downtime for maintenance. Meanwhile, it is scratch-resistant and can adapt to high-speed and high-intensity production environments.

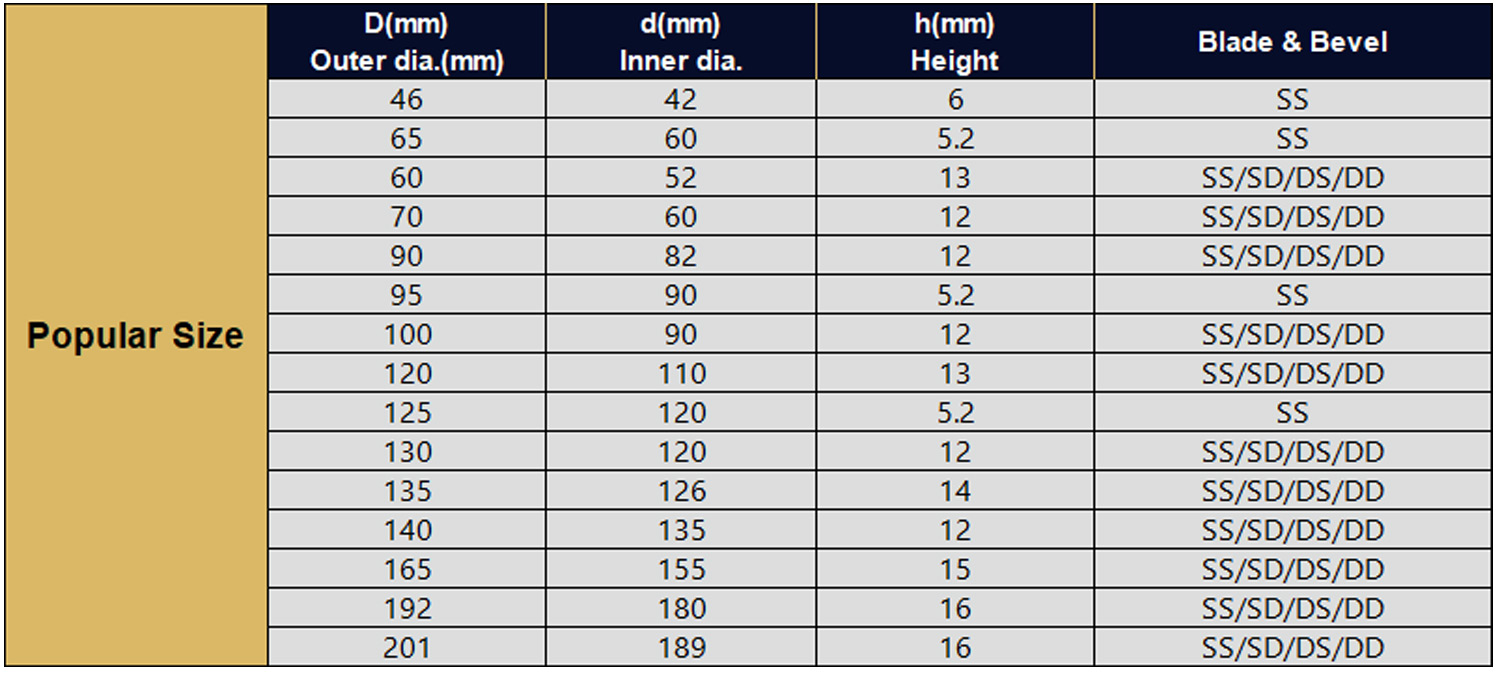

WINNEO pad printing rings parameter chart

We can manufacture any special specification rings according to your order.

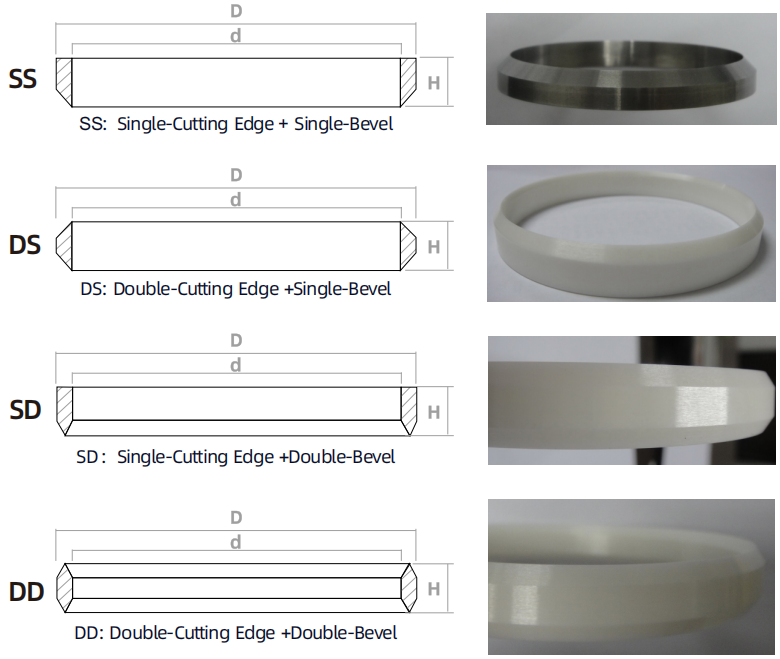

Four types of blade edges you can choose

If you are unsure how to choose the right type, you can contact us to get the type that best suits you.

100% Strict quality check

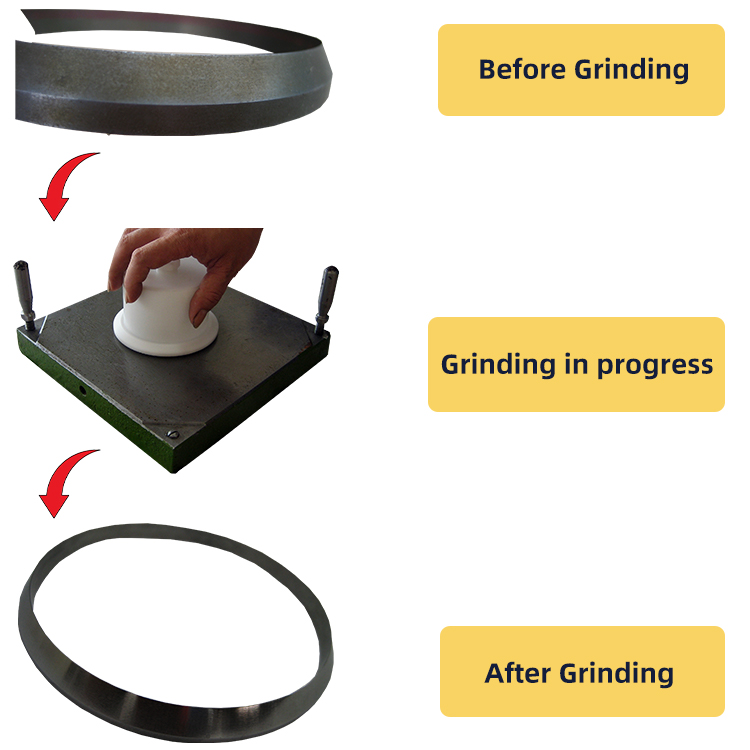

Tips for Reusing Pad Printing Rings

When your ink cup has been used for a long time, the ring blade may has some abrasion or small gaps (gaps not over 0.03mm depth), you can regrind it through a special grinding plate, so that you can reuse it. This method will help you reduce your cost greatly and it also more environmental friendly.

If you need instructional videos on the grinding process, feel free to contact us.

Raw Material Validation

Our raw materials have passed quality certification. Ensure the products meets high standards in performance and durability, reducing replacement frequency and maintenance costs.

Safety Shipment

Triple-layer packaging ensures product stability and safety during transportation, WINNEO delivers high-quality products to customer.

Customer feedback

WINNEO Pad Printing Rings are highly praised by customers.

FAQ

1.What is the service life of a pad printing ring?

Affected by factors such as material and frequency of use.

Tungsten rings can usually scrape ink for more than 80 million times,

Ceramic rings can usually reach more than 8 million times.

2.How to select the appropriate specifications of pad printing ring?

Select based on the printing equipment model, pattern size and shape, and production precision requirements.

3.What to do if the knife edge of the pad printing ring is uneven?

Minor unevenness can be repaired by precision grinding;

If the wear/deformation is severe, the ring needs to be replaced to avoid affecting ink control and printing accuracy.

4.Can special-specification pad printing rings be customized?

Yes, customization is available according to requirements, including size, shape, knife edge angle, etc.

Work Time

Receive your information 24 hours a day

Beijing time: Monday to Friday 9:00-17:30